Greetings LD1, what it means is that a debate of viewpoints is a non-emotional effort to better communicate. I admitted in my original post that I was confused by the statements made prior to my 1st post and then established why. It also means that 4570 was very skillful in recognizing a need for visual instead of theoretical reasoning.

You used in this post that I was "incorrectly maintain" something while others claimed my need for "movement" was not valid or even required.

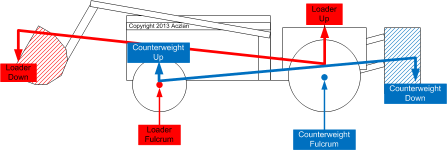

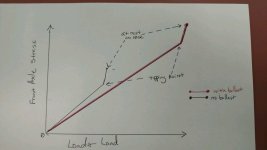

But 4570 in his second example skillfully demonstrated that movement was needed . . But that great force was required to create slight but important movement . . thus altering ground pressure . . a term never used until much much later after 4570's communications.

You asked if i am now understanding . . and my answer is yes . . because someone properly showed there was movement of the lever because ground "contact" is a variable. 4570 also showed just how much weight would potentially be needed on the short side of the lever (rear axle to 3 pt ballast) to create any measurable impact on the long side of the lever (rear axle to front of fel bucket).

I'm certain had you been around during the short debate . . that you would have recognized the need as 4570 did.

I also noticed a couple posters used words like "argue" which often implies emotion or rididity. I can't speak for others . . but you likely noticed mine reflect a willingness to communicate and listen to others points of view as long as unsafe operation is not acceptable . . and 4570 had some good points made

Just so no one misses my response to your posted question ive repeated it again here: "You asked if i am now understanding . . and my answer is yes . . because someone properly showed there was movement of the lever because ground "contact" is a variable. "