beenthere

Super Star Member

- Joined

- Aug 16, 2001

- Messages

- 18,555

- Location

- Southern Wisconsin, USA

- Tractor

- JD_4x2_Gator, JD_4300, JD_425, JD_455 AWS, added JD_455, JD_110, JD_X485(sold)

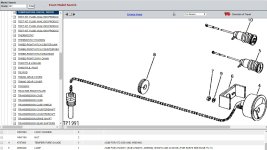

Thinking it is not a wire, but a capillary tube from the sensor to the indicator.

Part # AT67693

$156 part appears.

Note: How the capillary tube works.

Temperature Gauge | How It Works

Part # AT67693

$156 part appears.

Note: How the capillary tube works.

Temperature Gauge | How It Works

Attachments

Last edited: