allen in texas

Platinum Member

- Joined

- Oct 26, 2007

- Messages

- 919

- Location

- Levelland, TX

- Tractor

- Kubota Grand L 5740, loaded R1's w/640 lbs cast weight, 854 loader

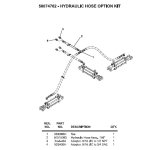

And I have a question about the hydraulics. This thing came with a pair of hoses that work off of one of my remotes on my tractor. One lever lowers the entire shredder and lowers the wings...sorta.

they are all interconnected, one direction of the lever will lower the deck but at the same time will try to raise the wings and vice versa. I hate it. I have had a set of hoses made up and added fittings so that the lowering of the deck is controlled by one lever and raising and lowering of the wings is controlled by another. the only thing I am concerned with is the fact that the cylinders were single acting and I am making them double acting, shouldn't be a problem on raising and lowering the deck but might cause a problem on the wings. Any body else come across this sort of situation? what say you?

BTW, I left the flail nation (sorta) because I have 2 jobs that are a labor each. That takes a LONG time with a 6 foot flail and the Bush hog was substantially lower priced than a tow-able 12 foot flail. I still use the flail.

they are all interconnected, one direction of the lever will lower the deck but at the same time will try to raise the wings and vice versa. I hate it. I have had a set of hoses made up and added fittings so that the lowering of the deck is controlled by one lever and raising and lowering of the wings is controlled by another. the only thing I am concerned with is the fact that the cylinders were single acting and I am making them double acting, shouldn't be a problem on raising and lowering the deck but might cause a problem on the wings. Any body else come across this sort of situation? what say you?

BTW, I left the flail nation (sorta) because I have 2 jobs that are a labor each. That takes a LONG time with a 6 foot flail and the Bush hog was substantially lower priced than a tow-able 12 foot flail. I still use the flail.

![20171004_132327[1].jpg 20171004_132327[1].jpg](https://www.tractorbynet.com/forums/data/attachments/453/453576-b6f47683ef1f6e1044db320be6f749a7.jpg)