You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Grapple project OPEN SOURCE

- Thread starter polemidis

- Start date

- Views: 51106

More options

Who Replied?

/ Grapple project OPEN SOURCE

#81

LD1

Epic Contributor

b) having that much of a bite force, gives me room to sacrifice a little more force in exchange of some wider angle and more opening. Teeth to teeth in opening (measured from inside) is 29" now. If I can make it to 35" or so it would be perfect.

remember you are not sacrificing anything. Just giving up force in the desired direction. All the while redirecting the excess force in the wrong direction working to rip your grapple lid right off its hinges. Going to a bigger cylinder and a less than ideal angle....not necessarily a good thing.

Dang it....

No worries as long as it does what you need it to do.

What make/model/brand is your grapple?

Now that I have a better understanding of the geometry etc, I had to deside at a few things. Go smaller to fit the 4" cylinder better, or going bigger and but a 6" cylinder. I tried bigger. By 3" in length and about 2" in height.

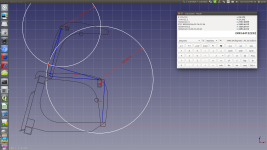

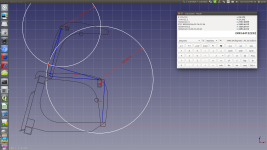

This is what I have now. (Some components are missing and others are out place, and I believe I have to buff up the hinges, put dont mind that for now). Bore size 2.5"

2490lbs at the closed position,

1190lbs at the opened

36.25in opening mouth

13ー the cylinder at closed end

6.2ー at the the opened

The grid is 4". If thats good enough I will start working on the material/hinge shape and add some dimensional drawings too. You suggest 3/8" thickness? I was thinking for 5/16" and just put gussets at the risky to bend places.:confused3:

Are these numbers more than enough? I mean I could make it a couple more inches bigger and lower these numbers. With the 6" cylinder I have space. Or try the other approach and go for a smaller grapple?

This is what I have now. (Some components are missing and others are out place, and I believe I have to buff up the hinges, put dont mind that for now). Bore size 2.5"

2490lbs at the closed position,

1190lbs at the opened

36.25in opening mouth

13ー the cylinder at closed end

6.2ー at the the opened

The grid is 4". If thats good enough I will start working on the material/hinge shape and add some dimensional drawings too. You suggest 3/8" thickness? I was thinking for 5/16" and just put gussets at the risky to bend places.:confused3:

Are these numbers more than enough? I mean I could make it a couple more inches bigger and lower these numbers. With the 6" cylinder I have space. Or try the other approach and go for a smaller grapple?

Last edited:

ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 33,727

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

No worries as long as it does what you need it to do.

What make/model/brand is your grapple?

I built a double claw grapple onto a Bobcat LoPro bucket. It works very well and has hundreds of hours of hard use under it's belt.

As I've stated earlier, I'm totally a practical application guy. Your approach is over my comprehension level. So I design by the desired end result. In my case I wanted a large opening. That created the position of my cylinders. I had no idea how much bite force I was going to have until I put it into action. I don't need more force. I'm just a bit disappointed that my design doesn't score any higher.

I struggled a lot with position of the cylinder tabs. Tack welded, cut loose, moved, tack welded, many times to get where I ended up. When fully open and rolled back my claws parallel my FEL frame and curl cylinders so I couldn't open any wider. This "big mouth" design gives me the ability to push loose brush up in a pile, then roll the grapple forward until the claws span most of the pile. Clamp, compress and pick up a huge pile of brush. In the other side I have ability to clamp onto thin material such as plate steel, steel fence posts, or whatever.

Still, just disappointed in my force numbers..... :ashamed:

Xfaxman

Super Star Member

- Joined

- Feb 8, 2013

- Messages

- 13,293

- Location

- Guthrie, OK

- Tractor

- Toolcat 5610 G - Bobcat V417 - TORO+Loader

No, don't go smaller. especially if used on brush.-----------------------

Are these numbers more than enough? I mean I could make it a couple more inches bigger and lower these numbers. With the 6" cylinder I have space. Or try the other approach and go for a smaller grapple?

Have you seen the medium duty from Loflin Fabrication? Loflin Fabrication

ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 33,727

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

No, don't go smaller. especially if used on brush.

Have you seen the medium duty from Loflin Fabrication? Loflin Fabrication

View attachment 526601

That's what I should have done. Made my frame mount tab taller and more forward, then used a shorter stouter cylinder. Famous last words!!!

Do you know what the stroke length is on that cylinder?

Edit: Never mind, I checked out your link. They say 10". My pea size brain can't figure out how to make that work on mine. My claws and apron must be shorter than theirs. I'll have to take some more measurements of mine.

LD1

Epic Contributor

Not sure why you are still so adamant on wanting to use a 4" or 6" stroke cylinder....when all the mfgs that spend thousands on designing and engineering all use 8" or 10" stroke cylinders.

Why re-invent the wheel.

But you have designing software ability. So whatever works for you.

I'd go no less than 3/8". That's pretty much standard on light and medium grapples.

Why re-invent the wheel.

But you have designing software ability. So whatever works for you.

I'd go no less than 3/8". That's pretty much standard on light and medium grapples.

LD1

Epic Contributor

I built a double claw grapple onto a Bobcat LoPro bucket. It works very well and has hundreds of hours of hard use under it's belt.

As I've stated earlier, I'm totally a practical application guy. Your approach is over my comprehension level. So I design by the desired end result. In my case I wanted a large opening. That created the position of my cylinders. I had no idea how much bite force I was going to have until I put it into action. I don't need more force. I'm just a bit disappointed that my design doesn't score any higher.

I struggled a lot with position of the cylinder tabs. Tack welded, cut loose, moved, tack welded, many times to get where I ended up. When fully open and rolled back my claws parallel my FEL frame and curl cylinders so I couldn't open any wider. This "big mouth" design gives me the ability to push loose brush up in a pile, then roll the grapple forward until the claws span most of the pile. Clamp, compress and pick up a huge pile of brush. In the other side I have ability to clamp onto thin material such as plate steel, steel fence posts, or whatever.

Still, just disappointed in my force numbers..... :ashamed:

]

Nothing to be disappointed about. You designed it and made it work to your satisfaction...so what more can you ask?

deanocraft

Silver Member

I'm following this thread and I really have enjoyed the mathematical approach. I wish one of my high school math teachers had used a real world example approach to show how math can be used after you pass the test... I think it would have really held the interest of many students. I did fine in math, but I remember thinking how I would never use that in real life!

Now I haven't checked the math for accuracy... Nor have I confirmed that the formulas are proper... But I like the approach!

Now I haven't checked the math for accuracy... Nor have I confirmed that the formulas are proper... But I like the approach!

ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 33,727

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

I'm following this thread and I really have enjoyed the mathematical approach. I wish one of my high school math teachers had used a real world example approach to show how math can be used after you pass the test... I think it would have really held the interest of many students. I did fine in math, but I remember thinking how I would never use that in real life!

Now I haven't checked the math for accuracy... Nor have I confirmed that the formulas are proper... But I like the approach!

I also like the approach. Just not able to execute it very well.

In reference to your high school comments. There's a frequent member on here, can't remember his name, who's signature motto is something like this: "Another day that I haven't used Algebra".

Zebrafive

Super Member

If anyone has a different brand grapple and would like me to calculate the bite force.....All I need is 4 measurements. Close your grapple lid and give be the 3 dimensions that form the triangle (A,B,and C in my drawings), and then the dimension from the lid hinge to the teeth. And I can calculate assuming a 2" cylinder and 2500psi. See how the geometry of some other grapples compare:laughing:

Where is your drawing for ID of points A B C?

Or please ID points A, B, & C Drawings in this post did NOT have an A, B, or C

By "lid hinge to the teeth" I think you mean point at end of lid. Or straight line length of "lid"

I have a commercial built grapple by RakeMaster I would like you to calculate.

I can also check my cylinder size. My tractor only has 2250psi

Xfaxman

Super Star Member

- Joined

- Feb 8, 2013

- Messages

- 13,293

- Location

- Guthrie, OK

- Tractor

- Toolcat 5610 G - Bobcat V417 - TORO+Loader

That's what I should have done. Made my frame mount tab taller and more forward, then used a shorter stouter cylinder. Famous last words!!!

Do you know what the stroke length is on that cylinder?

Edit: Never mind, I checked out your link. They say 10". My pea size brain can't figure out how to make that work on mine. My claws and apron must be shorter than theirs. I'll have to take some more measurements of mine.

Yours looks like it is working pretty good. :thumbsup:

ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 33,727

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

Where is your drawing for ID of points A B C?

Or please ID points A, B, & C Drawings in this post did NOT have an A, B, or C

By "lid hinge to the teeth" I think you mean point at end of lid. Or straight line length of "lid"

I have a commercial built grapple by RakeMaster I would like you to calculate.

I can also check my cylinder size. My tractor only has 2250psi

Not trying to jump over LD1.

Measurements with claws closed.

A = distance from barrel end of cylinder pin to ram end of cylinder pin

B = distance from hinge pin of claw to ram end cylinder pin

C = distance from hinge pin of claw to barrel end of cylinder pin

D = distance from hinge pin of claw to tip of claw

ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 33,727

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

Yours looks like it is working pretty good. :thumbsup:

Thank you, yes if works fine. I'm just regretting little things I could have done to make it better. That is if I had retained what I learned in Geometry class.

LD1

Epic Contributor

Where is your drawing for ID of points A B C?

Or please ID points A, B, & C Drawings in this post did NOT have an A, B, or C

By "lid hinge to the teeth" I think you mean point at end of lid. Or straight line length of "lid"

I have a commercial built grapple by RakeMaster I would like you to calculate.

I can also check my cylinder size. My tractor only has 2250psi

See post #70

Just remember that bigger diameter cylinders are heavier. And every pound you have at the end of the loader is one less pound you can pick up with the grapple. I would use a flow control valve with a smaller diameter cylinder, if the force at the end of the jaws is still enough to get the job done.

Zebrafive

Super Member

Not trying to jump over LD1.

Measurements with claws closed.

A = distance from barrel end of cylinder pin to ram end of cylinder pin

B = distance from hinge pin of claw to ram end cylinder pin

C = distance from hinge pin of claw to barrel end of cylinder pin

D = distance from hinge pin of claw to tip of claw

Thanks!

See post #70

Thanks, picture/drawing was so small I missed it (A, B, C, labels) I will get them plus D and post for your calculations!

Zebrafive

Super Member

ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 33,727

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

Here's a couple of pictures of the RakeMaster grapple

That thing is very well built!!!! Are your cylinders 2x8?? Anxious to see your "C" measurement. Also would like to see a pic with the claws open if you have one. Thanks!!!!