You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Miami pedestrian bridge collapse

- Thread starter California

- Start date

- Views: 26642

- Status

- Not open for further replies.

More options

Who Replied?

/ Miami pedestrian bridge collapse

#61

/pine

Super Star Member

- Joined

- Mar 4, 2009

- Messages

- 15,763

Documents obtained by The Associated Press through a public-records request show that the Florida Department of Transportation in October 2016 ordered Florida International University and its contractors to move one of the bridge's main support structures 11 feet north to the edge of a canal, widening the gap between the crossing's end supports and requiring some new structural design.

Key design change stymied cost, schedule of bridge in deadly Florida collapse | Fox News

There are some that try to post useful info and a bunch more that just want to be antagonistic.

antagonistic should mean peaceful:

agonistic

adjective

1.combative; striving to overcome in argument.

/pine

Super Star Member

- Joined

- Mar 4, 2009

- Messages

- 15,763

There are some that try to post useful info....

you mean like this one? :

Good work...they should make that post a "sticky"two = 2

buckeyefarmer

Epic Contributor

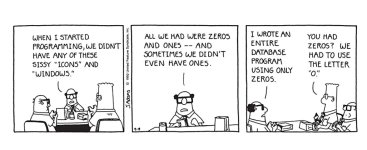

11 kinds, those that understand binary, those that dont, those that dont care."There are 10 kinds of people in the world...those who understand binary and those that don't"

From an old programming class...

Wnc3

Gold Member

- Joined

- Feb 18, 2012

- Messages

- 377

- Location

- S.E., Texas

- Tractor

- John Deere 820 utility, John Deere 5525, 997 JD Zmower, Komatsu PC 35 miniExcavator

Here's what I have put together as hypotheses based on what I've read so far. Surely this will be superseded by more accurate information as the picture becomes clearer.

1) I've read the future tower and cables are decorative. The structure as put in place was complete as designed to carry stress.

2) The design is experimental. It is a (theoretical) I-beam. The 'chords' (diagonals containing post-stressing threaded rods) constitute the center one-third of the I-beam.

3) The initial design proposed that the trucks to carry it into place would have platforms on top to distribute stress, and would support the bridge very near its ends as the bridge was carried into place.

4) Due to curbs or something on the street, the truck carrying the North end of the bridge instead carried it some 20 ft from its end, a point not designed for lifting stress. Additionally the platforms in the initial design weren't used between the trucks and the bottom of the bridge. These two factors concentrated stress onto a narrow location not designed to bear lifting force.

5) After it was in place the project engineer, advisor to the contractor, phoned the state DOT and described unexpected cracks.

6) Post-stressing rods, I think in the chords, were found to have less tension than spec. A crew was tightening a chord, I think up on top above that unplanned lift point and 20 out from the North end, when the structure fell.

7) I've seen conjecture that when the bridge was carried 20 ft from its end, the cantilevered last 20 ft stretched the post-tensioning rods in the chords near to breaking. So after the bridge was placed and its ends bore its weight, a rod (more?) was slack. Possibly allowing sag and the crack noticed by the project engineer.

8) The post-tensioning specialty crew was present when the bridge fell. I think up on top tightening a rod back to designed tension. But I think it snapped before it reached spec. Alternately, the crew might have been directed to apply tension to raise the bridge back up to specified height (and close the observed cracks) without regard for the strength of the rod.

9) More conjecture, unverified: I saw a photo of one tensioning rod sticking out of the roof maybe 8 ft, as if it shot out there after snapping. If it were intact it would still be in its crumpled chord. Another photo showed a different (?) post-tensioning rod sticking out of the roof several ft with the hydraulic tightening tool still attached to it. One employee of the post-stress specialty contractor died, two injured. I assume they were operating that tool.

10) A moment after it fell, above the fail point there is an empty man-lift (I think for that crew) and a heavy crane whose hook is empty. I assume the crane is there to lift that hydraulic tool and perhaps to provide hydraulic power. One witness said a heavy object fell from the crane hook causing the collapse. Possibly a trailer-mounted hydraulic pump? That was a student interviewed by tv at the site, this may be real or only what he thought he saw. I would think tensioning a weakened rod, which then snapped, is a more likely cause. Maybe the falling hydraulic lines pulled the hydraulic pump off its crane sling causing the fall that the student witnessed. Pure guessing on my part, later we shall see what really happened.

11) At the moment, I think tightening the pre-stressing rod that had stretched due to overload, caused that rod to snap leaving the bridge without the support that rod was designed to provide. The bridge fell. And there are obviously gross mis-calculations somewhere in the design and install processes given this result.

All this is my opinion. We shall see how close it is to what is found in the final report.

That was really well said and thought out.

I also think when the rod snapped while adding tension and that set off the chain of events.

Thanks for your input.

California

Super Star Member

- Joined

- Jan 22, 2004

- Messages

- 16,680

- Location

- An hour north of San Francisco

- Tractor

- Yanmar YM240 Yanmar YM186D

What's the fourth?11 kinds, those that understand binary, those that dont, those that dont care.

California

Super Star Member

- Joined

- Jan 22, 2004

- Messages

- 16,680

- Location

- An hour north of San Francisco

- Tractor

- Yanmar YM240 Yanmar YM186D

Thanks.That was really well said and thought out.

I also think when the rod snapped while adding tension and that set off the chain of events.

dragoneggs

Super Star Member

- Joined

- Jun 9, 2013

- Messages

- 14,548

- Location

- Seabeck, Washington

- Tractor

- Kubota BX-25D, Kubota Z122RKW-42

I agree. Nice plausible summary of events and cause. I appreciate the think through, Cali! I am a mechanical/structural engineer and haven't had the time to dive into this unfortunate disaster, but it sure seems an avoidable structural failure. Not my livelihood anymore but I would be interested in whether sizing was right or the adjusting was wrong or ???That was really well said and thought out.

I also think when the rod snapped while adding tension and that set off the chain of events.

Thanks for your input.

PILOON

Super Star Member

Not failure related.... but did anyone else notice that almost to a T, as soon as it happened, everyone left their cars and trucks and ran TOWARDS the disaster, most likely wanting to help. Puts a little faith back in humanity.

Yes. saw that and agree with U.

Another thing that struck me is that there were 'cross walks' a mere 100 ft away which suggests 'pork barreling' (think is right term).

Did one get injured jay walking illegally?

Or walking while texting?

Are those students so lazy not to walk 100 ft more to cross safely?

California

Super Star Member

- Joined

- Jan 22, 2004

- Messages

- 16,680

- Location

- An hour north of San Francisco

- Tractor

- Yanmar YM240 Yanmar YM186D

My own theories - no validation so far - are:

1) Project management. A colleague once got away with titling her internal audit report on project cost control as: 'We can find no focus of authority and responsibility.' *

*

2) Not an engineer but my instinct as a amateur is the bridge was designed to be carried into place by lifting it at each end. With a panel between the truck and the bridge to spread stress. Instead the North end was lifted with the weight bearing on a narrow line 20 (?) ft in from the end, so that the end was cantilevered over that narrow lift point - overstressing that line (which is where the bridge first broke) and possibly stretching a tensioning rod. Additionally the chart lists no rods for the last chord. That has to be an error in that (early) version of the drawing or else a gross error when moving the bridge, to support the bridge in a way that stretched an unreinforced chord.

1) Project management. A colleague once got away with titling her internal audit report on project cost control as: 'We can find no focus of authority and responsibility.'

2) Not an engineer but my instinct as a amateur is the bridge was designed to be carried into place by lifting it at each end. With a panel between the truck and the bridge to spread stress. Instead the North end was lifted with the weight bearing on a narrow line 20 (?) ft in from the end, so that the end was cantilevered over that narrow lift point - overstressing that line (which is where the bridge first broke) and possibly stretching a tensioning rod. Additionally the chart lists no rods for the last chord. That has to be an error in that (early) version of the drawing or else a gross error when moving the bridge, to support the bridge in a way that stretched an unreinforced chord.

MossRoad

Super Moderator

- Joined

- Aug 31, 2001

- Messages

- 66,209

- Location

- South Bend, Indiana (near)

- Tractor

- Power Trac PT425 2001 Model Year

Yes. saw that and agree with U.

Another thing that struck me is that there were 'cross walks' a mere 100 ft away which suggests 'pork barreling' (think is right term).

Did one get injured jay walking illegally?

Or walking while texting?

Are those students so lazy not to walk 100 ft more to cross safely?

My daughter went to grad school at Pitt. There are several other universities in the same area. They are in a city setting, and crossing the streets are downright dangerous. Keeping pedestrians out of traffic is a worthy goal, for both the peds and the automobile drivers.

MossRoad

Super Moderator

- Joined

- Aug 31, 2001

- Messages

- 66,209

- Location

- South Bend, Indiana (near)

- Tractor

- Power Trac PT425 2001 Model Year

My own theories - no validation so far - are:

1) Project management. A colleague once got away with titling her internal audit report on project cost control as: 'We can find no focus of authority and responsibility.'*

2) Not an engineer but my instinct as a amateur is the bridge was designed to be carried into place by lifting it at each end. With a panel between the truck and the bridge to spread stress. Instead the North end was lifted with the weight bearing on a narrow line 20 (?) ft in from the end, so that the end was cantilevered over that narrow lift point - overstressing that line (which is where the bridge first broke) and possibly stretching a tensioning rod. Additionally the chart lists no rods for the last chord. That has to be an error in that (early) version of the drawing or else a gross error when moving the bridge, to support the bridge in a way that stretched an unreinforced chord.

I tend to agree with your assessment. I saw some pictures of how it was supposed to be moved and then how it was actually moved.... they didn't match. So there you have it. It was lifted from a point not meant for lifting, causing unexpected stress/stretch in the tensioning system and/or concrete, weakening it.

MossRoad

Super Moderator

- Joined

- Aug 31, 2001

- Messages

- 66,209

- Location

- South Bend, Indiana (near)

- Tractor

- Power Trac PT425 2001 Model Year

"There are 10 kinds of people in the world...those who understand binary and those that don't"

From an old programming class...

Attachments

California

Super Star Member

- Joined

- Jan 22, 2004

- Messages

- 16,680

- Location

- An hour north of San Francisco

- Tractor

- Yanmar YM240 Yanmar YM186D

A footnote I was drafting for my post above. After seeing Moss's cartoon I'll put it here instead:

*(footnote from above)

State DOT here. Long ago. Internal Audits branch. My colleague was sent out to analyze why the onsite project managers at construction field sites were screaming that they had lost all control over project costs because of transition from hand-kept cost records at the jobsite that they were responsible for, to primitive computerized reporting - where they filled out HQ-designed paper forms and mailed them in to be keypunched into cards (not necessarily timely), never to see their numbers added up before a printout was mailed back to them next month.

She wrote up her Audit Report and it was issued under the title: 'We Can Find No Focus of Authority and Responsibility.'

PILOON

Super Star Member

In Toronto, Canada, at a crosswalk you raise your arm, (hand) and all traffic comes to a stop as that indicates you intend to cross.

Fines are very strict and that system seems to work.

Fines are very strict and that system seems to work.

I like that. Oftentimes here it's hard to tell if someone is trying to use the crosswalk or waiting for the bus. (or just standing there.)In Toronto, Canada, at a crosswalk you raise your arm, (hand) and all traffic comes to a stop as that indicates you intend to cross.

Fines are very strict and that system seems to work.

buckeyefarmer

Epic Contributor

Its lots of students crossing a busy road. Unfortunately they went for bling instead of function.Yes. saw that and agree with U.

Another thing that struck me is that there were 'cross walks' a mere 100 ft away which suggests 'pork barreling' (think is right term).

Did one get injured jay walking illegally?

Or walking while texting?

Are those students so lazy not to walk 100 ft more to cross safely?

San Diego teen’s death led to construction of Florida bridge: report | fox5sandiego.com

MIAMI – The pedestrian bridge that collapsed near Florida International University killing six people was built to improve safety after an 18-year-old girl from San Diego died crossing the road a year earlier, officials said.

Florida International University freshman Alexis Davis was hit and killed by a motorist while crossing an eight-lane highway at Southwest 8th Street in August, the Miami Herald reported.

The bridge was supposed to enhance safety -- letting walkers and cyclists cross the busy street with less worry.

MIAMI – The pedestrian bridge that collapsed near Florida International University killing six people was built to improve safety after an 18-year-old girl from San Diego died crossing the road a year earlier, officials said.

Florida International University freshman Alexis Davis was hit and killed by a motorist while crossing an eight-lane highway at Southwest 8th Street in August, the Miami Herald reported.

The bridge was supposed to enhance safety -- letting walkers and cyclists cross the busy street with less worry.

MossRoad

Super Moderator

- Joined

- Aug 31, 2001

- Messages

- 66,209

- Location

- South Bend, Indiana (near)

- Tractor

- Power Trac PT425 2001 Model Year

8 lane highway + college students = problems.

- Status

- Not open for further replies.