I'm thinkin' second from the left.

Yes, the one who gave his wife an allowance and she spent before I could borrow it back, how'd you guess.................

I'm thinkin' second from the left.

"What these pyramids made of, 1/4" plate steel? I must of missed those pictures? "

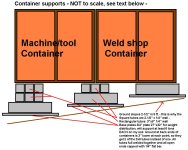

Nope, ain't no pics til they actually get DONE - base plates are 3/4" plate, tubing is either 2-1/2" x 1/4" wall or 3x8 rectangular x 1/4" wall. Here's a rough sketch with more 'splainin' - View attachment 560955

I should get a few pics manana, but just of cut pieces and my VERY temporary "crane" for those lightweight 350 pound tubes...Steve

Might be a good time to introduce Dual-Shield Flux Core wire to the MM252s diet.

You still may have to set up a bit of a windbreak, though....

everyone knows its windy - Google Search

there's a total of 101 feet of cable; some red, some black, electrons don't care so I can mix/match whatever reaches - I also put the same connectors on my mig grounds, so if needed I can have any ground up to about 80 feet, and the 30A spool gun lets me reach up to 30 feet from the welder and ground it anywhere I want...

there's a total of 101 feet of cable; some red, some black, electrons don't care so I can mix/match whatever reaches - I also put the same connectors on my mig grounds, so if needed I can have any ground up to about 80 feet, and the 30A spool gun lets me reach up to 30 feet from the welder and ground it anywhere I want...

except for the 3/4" plate bases, which will be 27"x32" at each location - oh, and a couple shots of my new "temporary helper" - works great for getting steel from the wall near the door to the bandsaw - that piece of tube weighed just under 200# before I cut another 3 feet off it... Steve

except for the 3/4" plate bases, which will be 27"x32" at each location - oh, and a couple shots of my new "temporary helper" - works great for getting steel from the wall near the door to the bandsaw - that piece of tube weighed just under 200# before I cut another 3 feet off it... Steve