angelugs

Bronze Member

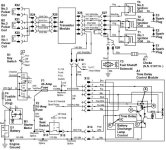

I have a JD 322 that is only running on 2 cylinders. I have a technical manual and have been trying to run down the problem. Basically I've been checking for continuity on the parts in the ignition system. Everything seems to be okay till I get to the ignition module. When I test the contacts one way I have continuity everywhere I'm supposed to. But when I switch the leads from my meter I have no continuity on the same contacts I just previously checked. The chart says I should have continuity on certain contacts regardless which way the meter leads are connected. It looks to me like I have a bad ignition module but at over $300.00 to replace it I don't want to THINK that's the problem. Has anyone else ever checked continuity on the ignition module's contacts and can verify they had flow no matter which meter lead was on the contacts?

Thanks in advance for your response.

Thanks in advance for your response.