rScotty

Super Member

- Joined

- Apr 21, 2001

- Messages

- 9,665

- Location

- Rural mountains - Colorado

- Tractor

- Kubota M59, JD530, JD310SG. Restoring Yanmar YM165D

Biggest issue is that most of my projects need digging/leveling, not loading. Don稚 want to break my new tractor doing something it wasn稚 designed for.

Jbo

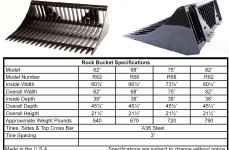

The smaller the bucket width, the easier it will dig. Standard buckets will dig, but not real well - although they will certainly dig faster than you and most of your friends can by hand. A bucket with long teeth or prongs or a rock bucket (below) will dig so much faster that it is often worth changing the bucket - or at least the cutting edge of the bucket - for digging and then changing back for scooping the loosened dirt.

For final leveling, I aim the bucket edge a little less than straight down, put enough pressure on the loader to raise the front wheels, and drive in reverse ... pulling the dirt.

rScotty