To finally get back to this thread, here's an update. Everything is installed and working. Only took 3 years. LOL. Actually, it's been finished for about a year, thanks to the help of a good friend. But I wanted to get some experience with the tractor before I posted an update.

If I were doing this today, I'd probably opt for a Kohler motor. I've heard a rumor Power-Trac offers a kit to make the swap (Subaru to Kohler) much easier. But that wasn't available when I started this project.

For the project, I needed to:

+ modify the pump mount weldment to match the new engine's bolt pattern.

+ create new engine "stands" (DOM tubing) so the engine sits at the same height as the original

+ cut out the rear of the tub to accommodate the new engine's slightly larger footprint and enable easy cleaning of the intake screen

+ increase the size of the wheel motor mounts to hold the slightly longer new wheel motors

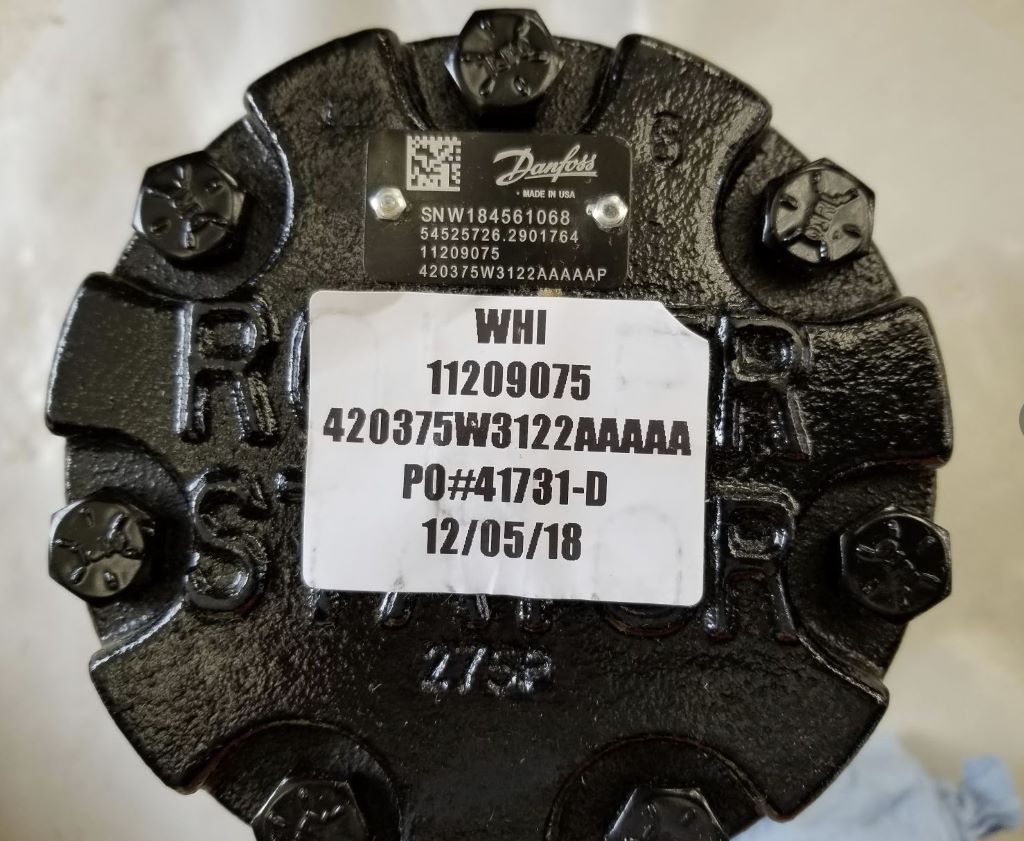

For the wheel motors, I increased the capacity from 14.2 cu. in. to 22.8 cu. in. The the tractor was very fast with the previous wheel motors. I would estimate top speed was approaching 10 mph (same as my zero turn mower). The current speed is about 6 mph. This is fast enough for my use as I'm happy to trade speed for additional motor torque. The difference is literally night and day. I have no trouble climbing any hill and can spin the wheels, when pushing into a dirt pile, without a problem. I could go on about the differences due to the extra horsepower and wheel motor torque, but let me just say it completely transformed the tractor. The downside is additional strain on the tractor frame that may cause future problems. Also, the additional engine power can generate a lot more hydraulic heat...beyond the cooling capacity of the current configuration. I'm going to install a temp gauge so I can monitor the hydraulic oil temperature, which should never get above 80 degrees C.

Here's a few pictures plus some additional tweaks I made while working on the tractor.

Tub cut out.

A weldment was then fabricated to ensure the tub couldn't flex and to enable easy access for cleaning and filter changes.

Here's the final assembly.

The new wheel motor I used (1/2" longer than original).

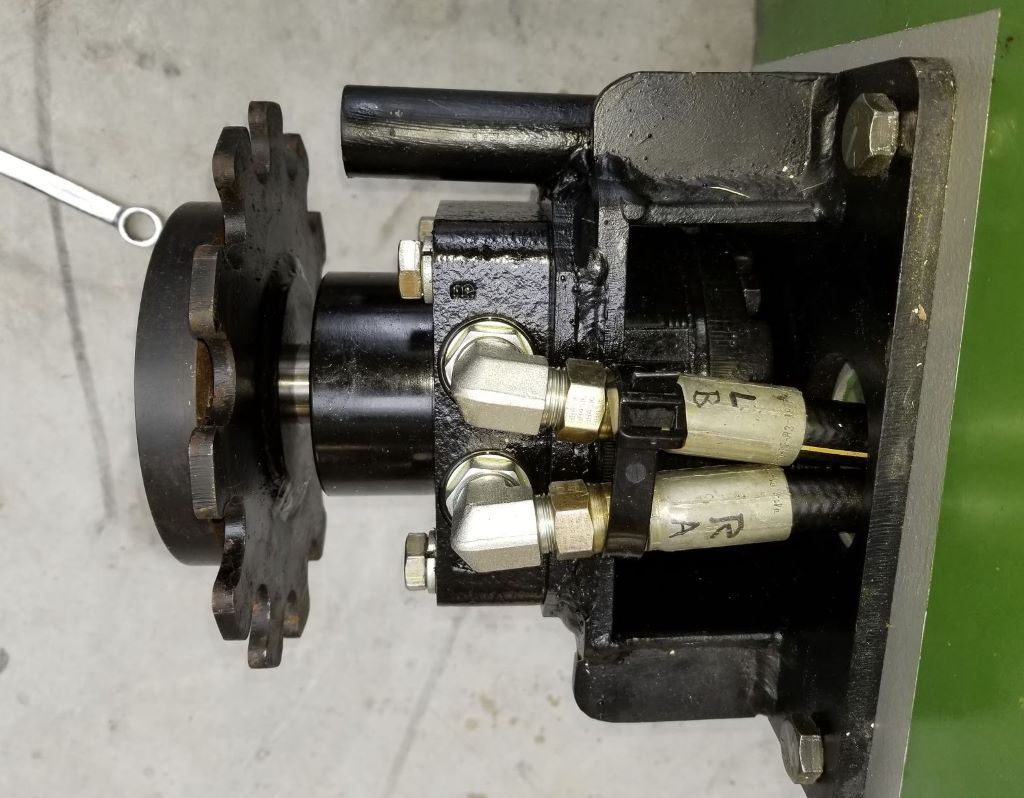

Modified motor mount.

Final assembly.

As mentioned numerous times here, the Power-Trac parking brake solution doesn't work very well. So we mounted a lever on the left side that uses a cable and pulley arrangement. This works much better.

I also felt it was necessary to do something about the muffler heat. We fabricated a rockwool insulated assembly to surround the muffler. We then mounted a fan on the opposite side to blow air across the muffler for additional cooling. I can now rest my hand on the battery tray without getting burned.

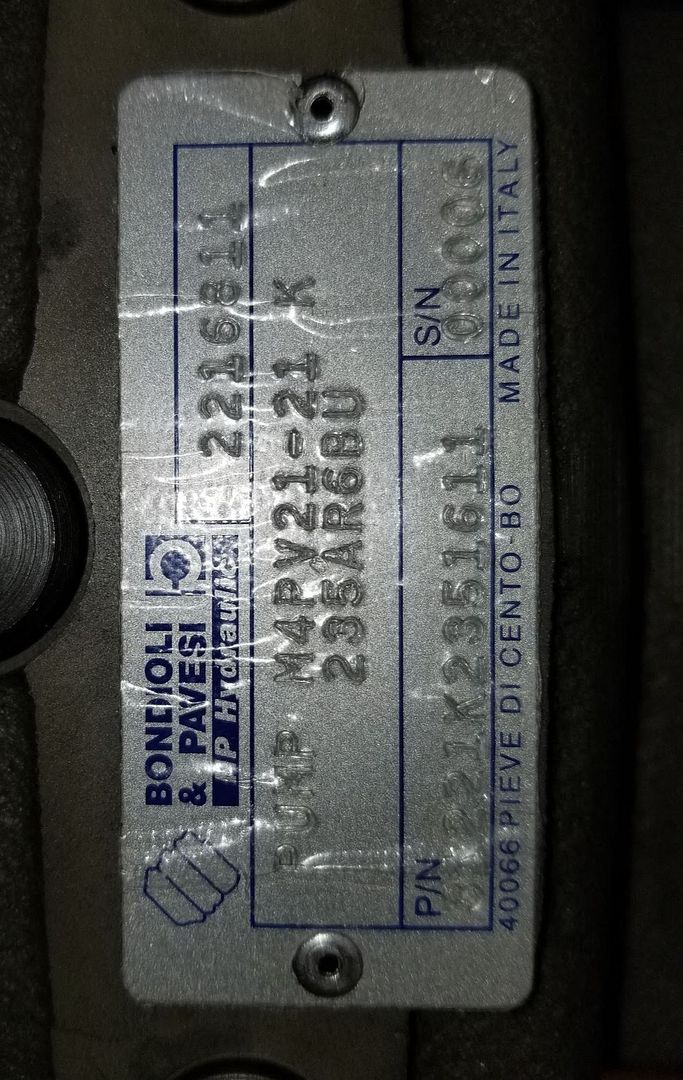

I bought a new Bondioli and Pavesi pump. It's the same 21 cc pump as originally installed. Here's the model number.

And finally, some additional tweaks in no particular order...

Relocated exhaust exit.

Rear hood stops...allows internal swing arm to be removed, freeing up space for the spark plug wires (no rubbing).

New lights. These lights are fantastic. I like the "look" of the old lights better myself...but these work so much better with less battery drain.