OP

jpilk99

Gold Member

- Joined

- Feb 19, 2011

- Messages

- 369

- Location

- Bolton, MA

- Tractor

- 1983 Ford 1700, 4WD, 770 Loader, Woods backhoe, Woods brush hog,etc.

Everything you've done sounds good to me.

If there is no wire coming out from under the flywheel or anywhere else then there are no points.

The only thing I can think of at this point is that the new magneto/coil that you bought is no good. Can you remove one from a running engine and try that?

If you remove the kill wire from the coil you've removed anything that can keep the engine from sparking so then the new coil should work.

I don't think I have a spare coil laying around or I'd take a picture and post it.

What brand/model of engine are you working on? I might be telling you totally the wrong information too.

Thanks so much PMS

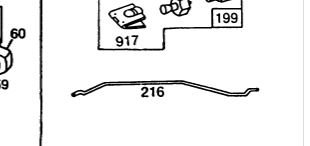

I'm going to take the coil off, clean the snot out of everything (magnets, connection point(s) of coil, ...anything) and then re-install it. Am I correct that you want the coil as close as possible to rotor/fly-wheel without touching? Or is there a certain gap, like a spark plug, that it should be back from the magnets? I honestly just try to orient the new in the exact same position/proximity as old....

Maybe I'll upload some more pics. Thanks so much.

Jay