LD1

Epic Contributor

I appreciate the info that the motor I linked to was not really a genuine 5hp motor. But what I didn't understand is why you never said it would be "good enough" since you said you used a 3 hp motor, and the motor I linked to could reliably only supply around 3 hp.

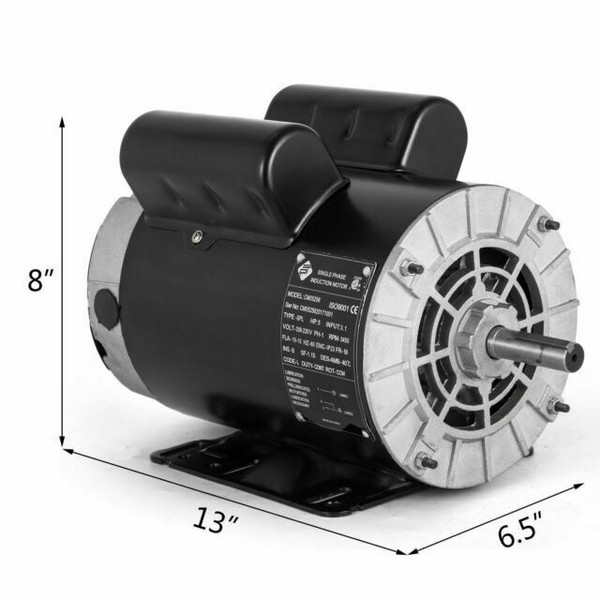

The reason I never said it was good enough is because I am saying that my 3hp really isnt good enough either. I would much rather use a 5hp motor. But I didnt have one. You see, my former company that closed the doors let me have (for free) all of the electric motors under 20HP. So I have about 40 of em. But only 3 of them were 5's and they were 1750 rpm's. But I have 4 or 5 of the 3hp/3600rpm motors. So I used what I had, cause it was free. If I was going out spending money to put this together, I would do it right. And also, that compressor motor you linked was an open motor. Too easy to get crap where it isnt supposed to be. TEFC is the way to go on a splitter.

IConsidering the intermittent loading in this application, and if he puts a micro switch and a contactor on it, it would not even be running 100% of the time, wouldn't this motor serve the desired purpose?

I also am thinking anyone on here who builds their own stuff, is not going to run the ram to the end of it's stroke and hold it till the motor burns up, or actually hold it into a piece of wood very long if it's not making any progress. Just trying to balance theory with real world practice and of course cost plays a big part.

I understand the balancing of theory and real world. The idea behind running the ram to the end to see what the amp draw is, was to see what it requires for the pump to make max pressure. Because while actually splitting wood, unless you have an amp meter or pressure gauge that you watch constantly, there is no way to know what you are actually doing. The the idea is to size a motor large enough to cover full pressure.

Even if it is only once in a blue moon that you spike the pressure/amps, it is doing permanent and non-reversible damage to the motor that will eventually burn it up.

And while things are working on my 3 hp currently. The 3hp 8 amp rated with 1.15SF is actually capable of more power than the 15A 5HP 1.0SF motor you listed. Converting it to power(watts, or VA) @230v, the motor you listed is 3450. My 8A 3 phase is slightly over 3800 accounting for the SF. And the fact that it actually took 11A to open the relief, thats a power of ~4500. Converting that back to a useful 230v singe phase number and you get 19.8A of power required.

All this means is: My 3hp is undersized and will fail sooner than a 5hp motor would. How much sooner I dont know. But the motor is/was free and I plan on finding out. The 5HP SPL compressor motor you linked, same story. It is undersized. (and open housing). Given it is undersized a bit more, and open, thats just all the sooner it will fail.