Pettrix

Platinum Member

I had some glulam beams installed on my new house build. I am in Arizona so it was hot & dry and the beams were installed in less than 1 week after being delivered. The roof was put on and now I am noticing some checking in that glulam beam. I was told that checking is normal, especially in a hot climate but I feel uneasy about it so I contacted the glulam manufacturer and they are looking into it.

Can a glulam beam be fixed on site/installed? I've seen some online photos of them using epoxy and lag bolts to shore up the beam.

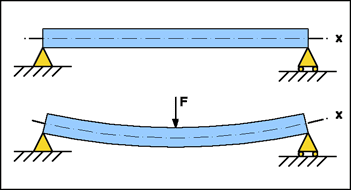

On mine, it's the bottom board that has checking in it. I know that board is under tension since it is the bottom board.

Any help would be appreciated...

Can a glulam beam be fixed on site/installed? I've seen some online photos of them using epoxy and lag bolts to shore up the beam.

On mine, it's the bottom board that has checking in it. I know that board is under tension since it is the bottom board.

Any help would be appreciated...