A single acting cylinder on my lift is squirting oil out the vent, so I assume the cylinder seal is bad. The check valve has 4 lines coming into it, I assume because it's synchronized with the leveling cylinder on the basket. My question is what is the safe way to relieve the pressure on the cylinder so I can remove it?

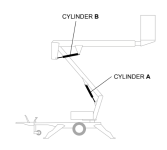

Here's a stick figure of the lift, I need to rebuild cylinder B:

The lift is in the rest position, so I can't see there being any mechanical forces on the cylinder shown by red arrow:

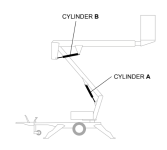

Here's the whole lift:

Here's a stick figure of the lift, I need to rebuild cylinder B:

The lift is in the rest position, so I can't see there being any mechanical forces on the cylinder shown by red arrow:

Here's the whole lift: