mike69440

Elite Member

- Joined

- Jun 2, 2005

- Messages

- 3,377

- Location

- Central NH (God's Country)

- Tractor

- 2005 L39 Kubota, 2020 Polaris 570 Sportsman, 2006 RTV 900, 2019 RTV1100C, 1997 Komatsu PC75UU2E w/ Thumb & Blade, 2013 Mahindra Max28XL Shuttle plus many attachments

There is a possible solution for the weak curl of the Loader.

First off, the 1400Lb Lift at the pins just is not honest.

The Loader manual states that the 1402 Lbs lift at the pins is developed at 2175 PSI System Pressure, 100 PSI more than what the relief valve is actually set at. I read that other people ford the relief at only1,800 psi

That no big deal as the little thing will lift approx. 1,200 Lbs. at the pins and that is better than other tractors of its size. For instance, a JD tractor the same size as the MaX28 has 35mm lift cylinders on the JD 130 loader, while the Max28 & Max 26 has lift 45mm cylinders.

But the weak part of the loader is the scrawny 35 mm Bore, 25 Mm Rod x 425 Stroke (650 retracted /1075mm extended) length bucket cylinders.

Stuff the bucket into a pile and most situations it does not have the beans to curl out a scoop of material. The Loader with a QA must even be weaker.

The loader was designed that way for a few reasons. If you are aggressive, you could bend the loader and tip the tractor, prying with the outside edge of the bucket.

The ML205 loader is not really sturdy. and should not be used as a battering ram.

However, if you are reasonable, stronger curl cylinders would boost machine capability greatly.

I looked really hard for a pair of cylinders. None to be found with the correct stroke or extended length, pin size . etc.

1.5" bore would be nice, a, 34% increase in force. 40mm is even better 40mm bore would provide 66% more oomph!.

The Loader on the new 1526 just could save the day.

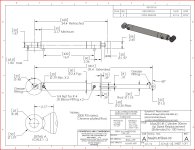

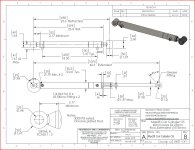

While it has just a bit more lift capability than the Max28, it cones with 40 mm bucket cylinders that have a 453 mm stroke, (644 retracted /1097mm extended) length bucket cylinders

Mahindra PN is KMW31502148.

The 644mm retracted length of the 1526's loader cylinder is a close match for the 650mm of the 35mm cylinder, but a positive stop would need to be added to the loader arms and bucket to prevent excessive extension.

My L39 Kubota has positive stops. I would have to fabricate and weld them to the Ml205 loader.

The tube ends would need to be trimmed, but that is not a difficult job.

As long as corner edge of the bucket is not used as a pry bar with reckless abandon, especially while driving the tractor forward, the loader should handle the increased power, loading. and stress.

First off, the 1400Lb Lift at the pins just is not honest.

The Loader manual states that the 1402 Lbs lift at the pins is developed at 2175 PSI System Pressure, 100 PSI more than what the relief valve is actually set at. I read that other people ford the relief at only1,800 psi

That no big deal as the little thing will lift approx. 1,200 Lbs. at the pins and that is better than other tractors of its size. For instance, a JD tractor the same size as the MaX28 has 35mm lift cylinders on the JD 130 loader, while the Max28 & Max 26 has lift 45mm cylinders.

But the weak part of the loader is the scrawny 35 mm Bore, 25 Mm Rod x 425 Stroke (650 retracted /1075mm extended) length bucket cylinders.

Stuff the bucket into a pile and most situations it does not have the beans to curl out a scoop of material. The Loader with a QA must even be weaker.

The loader was designed that way for a few reasons. If you are aggressive, you could bend the loader and tip the tractor, prying with the outside edge of the bucket.

The ML205 loader is not really sturdy. and should not be used as a battering ram.

However, if you are reasonable, stronger curl cylinders would boost machine capability greatly.

I looked really hard for a pair of cylinders. None to be found with the correct stroke or extended length, pin size . etc.

1.5" bore would be nice, a, 34% increase in force. 40mm is even better 40mm bore would provide 66% more oomph!.

The Loader on the new 1526 just could save the day.

While it has just a bit more lift capability than the Max28, it cones with 40 mm bucket cylinders that have a 453 mm stroke, (644 retracted /1097mm extended) length bucket cylinders

Mahindra PN is KMW31502148.

The 644mm retracted length of the 1526's loader cylinder is a close match for the 650mm of the 35mm cylinder, but a positive stop would need to be added to the loader arms and bucket to prevent excessive extension.

My L39 Kubota has positive stops. I would have to fabricate and weld them to the Ml205 loader.

The tube ends would need to be trimmed, but that is not a difficult job.

As long as corner edge of the bucket is not used as a pry bar with reckless abandon, especially while driving the tractor forward, the loader should handle the increased power, loading. and stress.

Last edited: