Not to anyone particular....

I was pulling T-posts out today giving this some thought. I don't have anything specifically designed to pull them, I just make a couple loops out of the middle of the chain, drop them over the post, walk back to the joystick and raise the bucket. I was operating the joystick with my left hand and got a little choppy one time lowering the post back to the ground so I could shake the chain off. The post swung under the bucket and I ended up shoving it right back into the ground (different hole) slicker than you know what. Because it took no effort at all, in my ground anyway, I wondered why the post driver had to be in the middle of the bucket, so this is what I came up with.

Bear with me, I don't have all the software loaded for my copier, so can't scan a drawing.

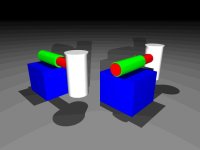

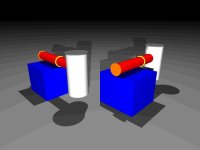

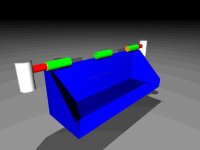

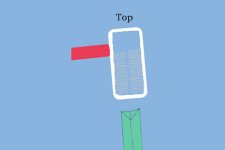

How about a bracket or two welded to the top of the bucket towards one side. My bota has about a 4" lip on the bucket that would work for this. To these brackets you would weld a pipe running parallel with the top edge of the bucket, side to side, maybe a foot long. This pipe would accept a slightly smaller diameter pipe or a solid steel rod. We'll call this pipe rod B. Rod B would be doing the work, so I was thinking maybe 2" diameter.

Let's say rod B is 18" long, so it slides into the pipe welded on top of the bucket and overhangs the side of the bucket. To the underside of rod B is welded a pipe to accept the T-post. You could even use the hand T-post driver. Because rod B swivels inside the other pipe, this "receiver" would always hang plumb, perpendicular to the ground.

You stick the T-post into this receiver, maybe use a bungee on one of those **** to hold it up in there, and the T-post should hang nice and plumb and be ready for you to lower the bucket and push it into the ground.

If anyone follows that build one and let me know if it works /forums/images/graemlins/grin.gif

I don't have access to all the goodies, but when the weather warms up I may build one for next year's snow fence.