rScotty

Super Member

- Joined

- Apr 21, 2001

- Messages

- 9,722

- Location

- Rural mountains - Colorado

- Tractor

- Kubota M59, JD530, JD310SG. Restoring Yanmar YM165D

On 4 Wheel Drive and Tire Ratios, there has been a lot written about the advantages in matching the tire size with the internal Front/Rear gear ratios - especially for 4wd. It turns out that this Front to Rear ratio is easy to measure.

It makes sense that in 2wd, Front to Rear tire size ratio doesn't much matter. But when shifting to 4wd, matching the F/R tire rolling circumference to the tractor's internal F/R drive train gear ratio does a lot to reduce the stress on the drive train and also makes steering easier as well.

You can check this effect on any tractor by simply measuring the distance that the front and rear tires travel in one revolution and comparing the measurements in 2wd and then again in 4wd.

All that is required is a flat piece of ground or road, some way to put a mark on the tire tread that will transfer to the ground, and a tape measure. I have marked tire treads with a blob of wet paint on a dry road, and a different time by using a short lag bolt into the tread for sand and snow.

In 2wd, measuring the distance between the marks the tires leave on the ground will tell us the rolling circumference (RC) of the tires. This RC may vary from the manufacturing spec, but in 2wd without any tire slippage what we are measuring is the true rolling circumference for that tire on that tractor. We are also automatically accounting for factors like tread wear, inflation, and load.

Repeating the same measurement in 4wd on high and low traction surfaces and comparing with the 2wd numbers we got gives good insight as to what is actually happening when we shift into 4wd.

We know that a measured difference from the 2wd numbers has got to be the result of tire slippage. And we know that normally tractors are set up so that the front tires rotate about up to 5% more than the rears in order to maintain steering control. So we have some idea of what we are expecting to measure. But in spite of this I found that the first time I checked things the measurements didn't quite come out as I expected. That required some thinking.

It turns out that when we measure in 4wd the measurements are no longer simply showing independent rolling circumference for each tire. In 4wd the front and rears are coupled together, so the measurements reflect a combination of how the tractor is loaded, how much traction the tires are getting, and also the internal F/R gear ratio of the drive train. On some surfaces you may find that the front tires are dragging the rears, and on other surfaces that the rears are push-sliding the fronts. Or maybe a bit of both. It is worth thinking about for awhile; this is handy information for protecting the drive train.

BTW, you'll hear the overdriven ratio between 2wd and 4wd expressed as a percentage difference. It is often called the Front-to-Rear Overdriven Ratio, and a commonly heard figure is that you want to be 5% or less overdriven. These measurements will give you that % ratio for your tractor by comparing the 2wd F/R ratio with the 4wd F/R ratio.

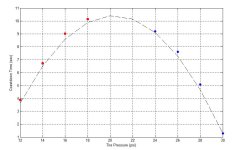

Bottom line is that there is no perfect ratio. On slippery surfaces the drivetrain can protect itself pretty much regardless of any ratio difference. But when traction increases, so does drive train stress.

Good Luck,

rScotty

Last edited: