Kyle_in_Tex

Super Star Member

So my rockshaft stopped working correctly some time ago and I haven't really had to do any box blading or anything precise. It would still go up and down, just not in proportion to the lever. I finally decided to see what the heck was wrong.

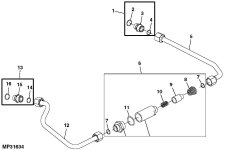

I can tell you my fix was not costly, but it took me about 8 hours to repair. I could do it over again, knowing the job and exactly what is needed in about 3 -4 hours possibly. It was small snafuus that caused the job to take so much time. Having to make tools, and retap the hydraulic lines to the rockshaft filter. More on that later.

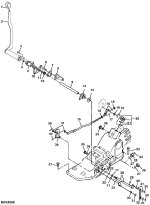

The problem was a rusty frozen control shaft going into the control valve. There are 2 shafts that go into the control valve. The top one is the actual 3 point lever that raises and lowers the 3 point. There is a 2nd shaft under that, that is connected to the 3 point lift arms and has some adjustability.

My lower shaft was rusted stuck from being13 years old, and much of that sitting outside.

You first have to take your seat off and the plastic base that covers everything under the seat. There are 4 seat bolts which are 13 mm and then the black plastic base has a bunch of 10mm bolts all around. You have to take off your A-B-C handle. A new orange cap is about $2 something. Also take off the black plastic handle on the 3 point hitch lever. You'll have to unhook the boot around your FEL loader joystick and work the base around it to get the whole thing off. Take pictures of everything so you can see how it goes back together. You will also need to take off the draft lowering speed control knob.

I can tell you my fix was not costly, but it took me about 8 hours to repair. I could do it over again, knowing the job and exactly what is needed in about 3 -4 hours possibly. It was small snafuus that caused the job to take so much time. Having to make tools, and retap the hydraulic lines to the rockshaft filter. More on that later.

The problem was a rusty frozen control shaft going into the control valve. There are 2 shafts that go into the control valve. The top one is the actual 3 point lever that raises and lowers the 3 point. There is a 2nd shaft under that, that is connected to the 3 point lift arms and has some adjustability.

My lower shaft was rusted stuck from being13 years old, and much of that sitting outside.

You first have to take your seat off and the plastic base that covers everything under the seat. There are 4 seat bolts which are 13 mm and then the black plastic base has a bunch of 10mm bolts all around. You have to take off your A-B-C handle. A new orange cap is about $2 something. Also take off the black plastic handle on the 3 point hitch lever. You'll have to unhook the boot around your FEL loader joystick and work the base around it to get the whole thing off. Take pictures of everything so you can see how it goes back together. You will also need to take off the draft lowering speed control knob.

Last edited: