marrt

Platinum Member

You guys may recall my thread, a few months ago, about the death of my Subaru. The root cause was gas in the oil. Seems to be happening a lot lately. I didn't bother tracking down the exact source of the leak. I suspect it was the carburetor but I don't know for sure. By the way, I still have the old engine if somebody needs a part.

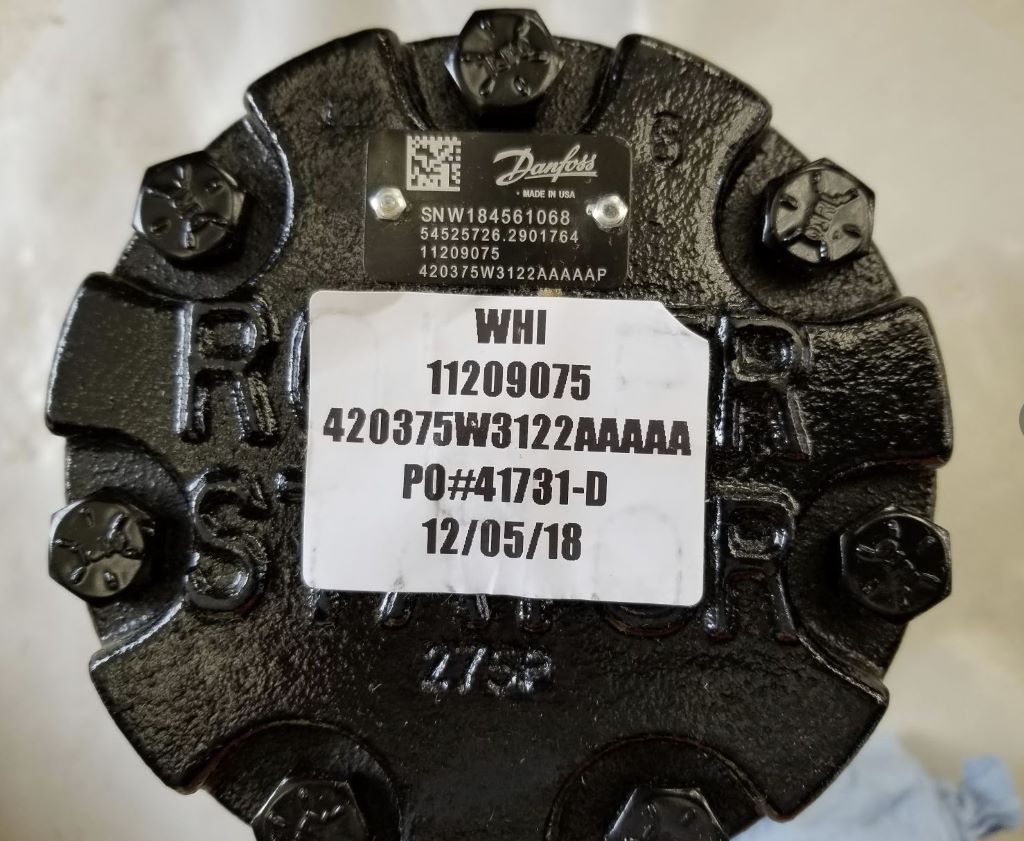

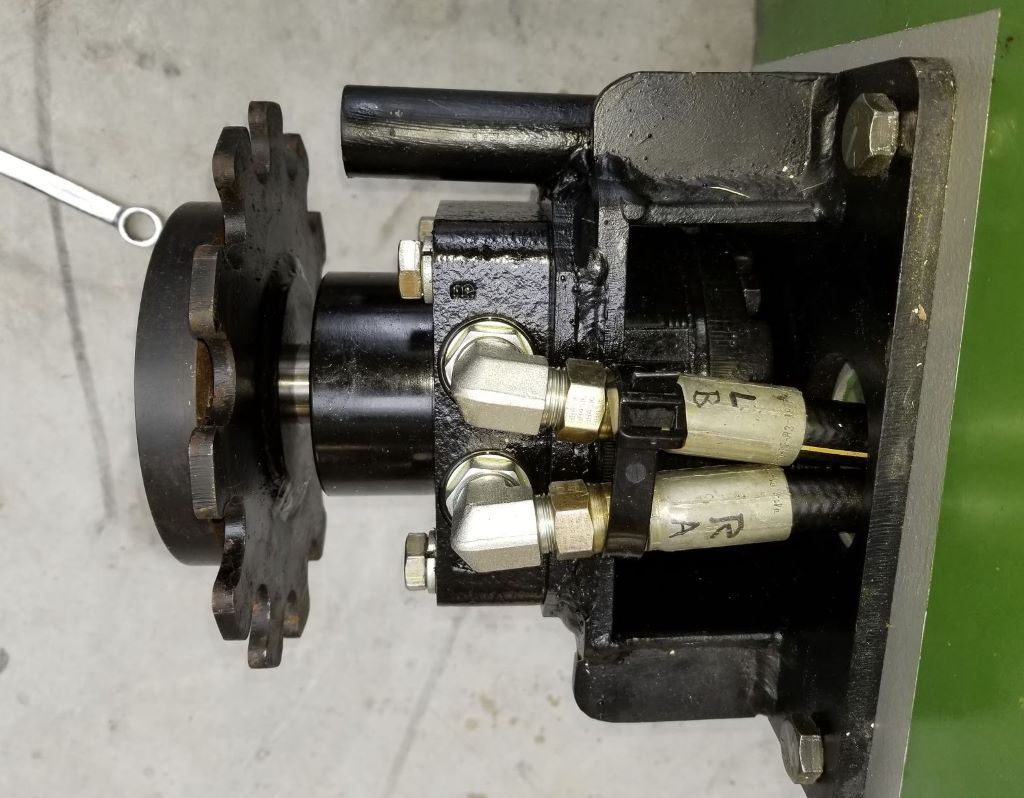

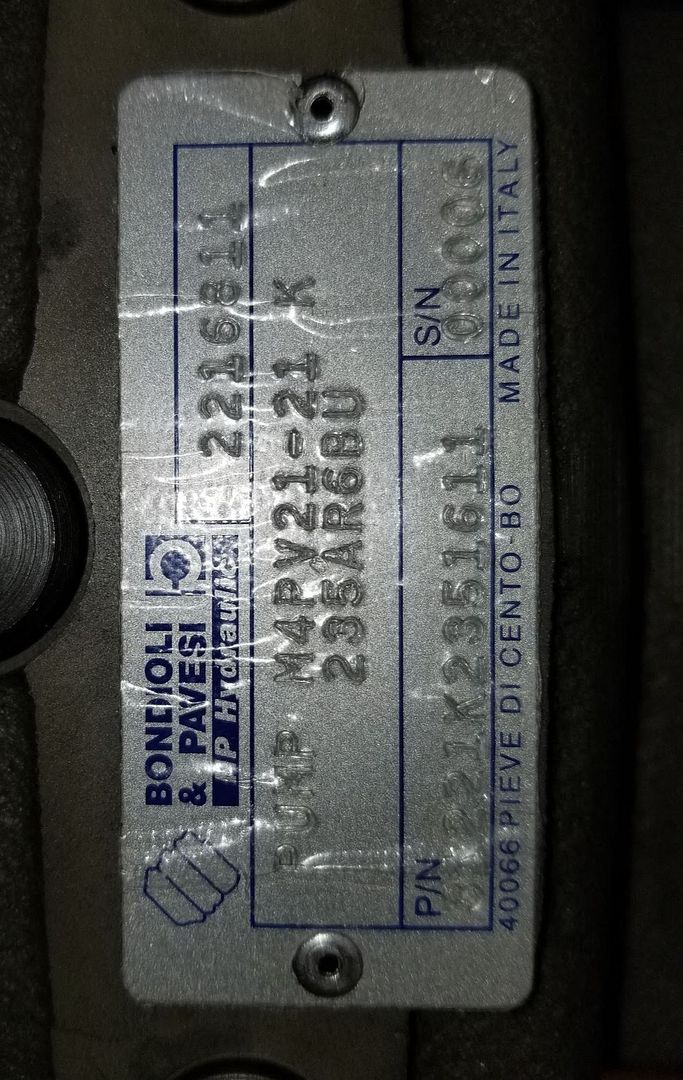

After a lot of hemming and hawing, I finally ordered the 35 hp Subaru "Generac" engine. I decided to go with this approach because I like to "mod" stuff especially Power-Tracs. I ordered larger will motors too. Probably don't need them with the larger engine but it should make the VD pump's life a little easier.

I'm ready to put everything back together but still have some concerns about cooling. And, given KentT's experience with the plastic fuel tank during a fire, I'm thinking about fabricating a steel tank. Also, this would be a good opportunity to relocate the hydraulic filter out of the tub and up near the tank. This could probably be accomplished by fabricating a smaller fuel tank so I have room.

I'll try to take a few pictures along the way.

After a lot of hemming and hawing, I finally ordered the 35 hp Subaru "Generac" engine. I decided to go with this approach because I like to "mod" stuff especially Power-Tracs. I ordered larger will motors too. Probably don't need them with the larger engine but it should make the VD pump's life a little easier.

I'm ready to put everything back together but still have some concerns about cooling. And, given KentT's experience with the plastic fuel tank during a fire, I'm thinking about fabricating a steel tank. Also, this would be a good opportunity to relocate the hydraulic filter out of the tub and up near the tank. This could probably be accomplished by fabricating a smaller fuel tank so I have room.

I'll try to take a few pictures along the way.

Last edited: