PILOON

Super Star Member

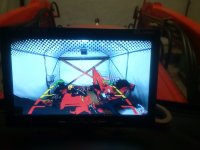

What U posted looks exactly like my $50 ish system which has all the options that are listed.

The camera units are designed for exterior mounting, so why not do so.

I also was doubting quality but for the price gave it a try and am super pleased.

I never did mount a front camera as planned but the rear is sure handy for snow blowing.

The specs they listed showed questionable cold limits but in practice I was pleased to discover our coldest weather had no negative effect and worked just fine.

I also discovered that just about any camera worked with the display.

The only concern was the extra fine wiring that they use considering the rugged environment a tractor poses as it does not take much to snag and destroy 26 gauge wire in a tractor environment.

The camera units are designed for exterior mounting, so why not do so.

I also was doubting quality but for the price gave it a try and am super pleased.

I never did mount a front camera as planned but the rear is sure handy for snow blowing.

The specs they listed showed questionable cold limits but in practice I was pleased to discover our coldest weather had no negative effect and worked just fine.

I also discovered that just about any camera worked with the display.

The only concern was the extra fine wiring that they use considering the rugged environment a tractor poses as it does not take much to snag and destroy 26 gauge wire in a tractor environment.