</font><font color="blueclass=small">( You are an engineer working for a company. What does your company do? Specialized only in one field or two, aren't they? )</font> We are an international company, both in manufacturing locations and sales, that designs and manufactures both standard and custom equipment for many different segments of industry and commercial use. We do make some equipment that is used in various areas in and related to farming, but most of it is not. I happen to design and oversee the manufacture of some of the custom products, including several that are farming related.

</font><font color="blueclass=small">( I am working WITH many manufacturers from metal forming to plastic forming to special casting to tool making for any materials (plastic, steel, aluminum, etc), etc etc. So, I know what I am talking about and know you aren't understanding what I am talking )</font>We cut, form, machine, and weld several different metals right here at our location. We also cut and machine several different types of plastics here. I design components out of metals, plastics, and composites. I also design and specify castings, components for power transmission, and hydraulic systems. Since I design custom equipment that is built right beside "catalog" units I often am very involved in the manufacturing process and methods of achieving the design w/out having special tooling made for each unit. I also work many outside suppliers, so I'm pretty sure I've got a pretty good grasp of what I'm talking about.

</font><font color="blueclass=small">( I guess people on the forum care and would like to know the truths behind the screens )</font>First, you are the only one questioning the design. Second, what are these screens you keep talking about?

</font><font color="blueclass=small">( . If another farmer had asked such questions questioning "hard design works" spend in existing products, you would probably be appreciating now. Why double-standart behaving when Nomad is questioning? Let me quess. It is easier to feel the community on your side against a foreigner like a nomad, isn't it? )</font> I have absolutely no problem with someone asking how a product works. I could care less about where you live. You don't ask how things work, you ask us to help you take someone elses work and use it to make yourself money by calling it your own. I take offense to your attacks on manufacturers and designs. Some of your irresponsible suggestions under the guise of an expert makes me leery of anything you post.

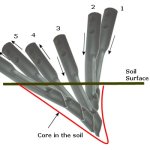

</font><font color="blueclass=small">( By the way, I am saying "there is no design work in existing tine" and you are saying "there is." Can we learn proof of the design work in it from you? Why is that tine curved? )</font> It exists, therefore it was the product of someone's imagination. It did not happen to show up on earth in that form by itself. It is curved b/c someone took the time and effort to specify that it should be curved. There I proved that some design work was performed.