BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

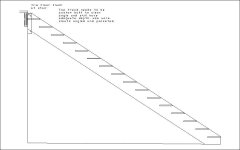

Yeah, love the DeWalt - 4 settings of aggressiveness and a blower is nice. Used it to radius the upper end of the risers so they'd swing on a 5/8" bolt between two pieces of 3x3x1/4" angle which are bolted to the double 2x12 across the face of the mezzanine.

When the stairs are down, the lower edge of the risers also rests on ANOTHER 5/8 bolt thru the angle iron pivots. Doubt it's gonna fall anytime soon....

The treads are 3/4 ply, 10" x 36", no center riser (weight saving) - so all treads have 3-1/2" ribs under them for stiffening/span. I finished all the tread install later today, no pics yet.

There'll be a chain fall on the built in place roof truss right above the lower end of the staircase, gotta weld up a spreader that'll pin on to the stair risers so I'm not trying to pull a tread up (loose) when I raise the steps out of the way... Steve

BTW, that spreader will be welded/(polished???) so I'm only 98% off topic here

When the stairs are down, the lower edge of the risers also rests on ANOTHER 5/8 bolt thru the angle iron pivots. Doubt it's gonna fall anytime soon....

The treads are 3/4 ply, 10" x 36", no center riser (weight saving) - so all treads have 3-1/2" ribs under them for stiffening/span. I finished all the tread install later today, no pics yet.

There'll be a chain fall on the built in place roof truss right above the lower end of the staircase, gotta weld up a spreader that'll pin on to the stair risers so I'm not trying to pull a tread up (loose) when I raise the steps out of the way... Steve

BTW, that spreader will be welded/(polished???) so I'm only 98% off topic here