Long time since I've updated things. So far we've processed 24 full cord.

Here is the pile of sawdust after 18 cord. The low spot between the pile and the processor was the walking path.

I finally got it over to my place this Sunday. RTV pulled it with no problems but I will say that you knew there was some weight back there.

I've gotten 24 bags done since Sunday.

We've broken down a few times but haven't broken the same thing twice.

Had a bearing ride out of its bore on the conveyor. Caused it to eat part of itself. Fixed that up and we now watch that bearing like a hawk.

Had the conveyor eat a piece of wood that was supposed to be ejected down the tipper chute. It went for a ride part way back down the underside. It bent up three paddles real bad. Had to straighten them on the underside to even roll it over. Fun

The box fans have solved the motor overheating issue, haven't had any issues since. We may try to do something different to avoid having the 120V tether. Maybe heat shields and ducting, maybe an automotive alternator driven off one of the engines. Then we'd have the available amperage to use 12v radiator fans.

FYI, A 22hp engine is too much for L-100 jaw couplings with a buna insert. It's actually borderline for the L-100 jaws themselves. We decided to try another set of L-100s anyway, this time with a urethane insert. That way we have the same size for both engines and hopefully continue to have universal parts. If we clean off the jaws again I guess we will have to step up to L-110 series couplings.

While we were down for the weekend with the failed motor coupling we decided to get the tipper built. We still need to add a gas spring to make switching directions easier but for now bungee cords will work.

General observations of the machine so far:

Firewood bags are great but my cobbled together bag holder was not. The biggest issue is that the slats could not handle the impact of wood falling from 10 feet in the air. We also found that we needed to upgrade to plywood walls. Especially with the tipper chute some chunks would fly down and tear holes in the bags when they hit between the slats. I also rebuilt the bag holders so that the sides are 6 inches off the ground. This allows us to use wider pallets (used to be 45 x 48 max).

We've had two issues using the plastic spring clamps to hold the bags in the holder. One, we had a bunch of them break when hit by firewood, and two if they don't break they often disappear down into the bags never to be seen from until they are unloaded. We are in the process of upgrading to metal clamps and now we're tethering the clamps to the box so we don't lose them.

When running with two people we ran 7 bags in two hours. So that is a little over a full cord an hour. The load of logs we were running was definitely on the small side so that number could go up with some larger diameter logs. Right now I'd say that something in the 14 to 16 inch range is ideal. That really keeps the person unloading bags and loading logs running!

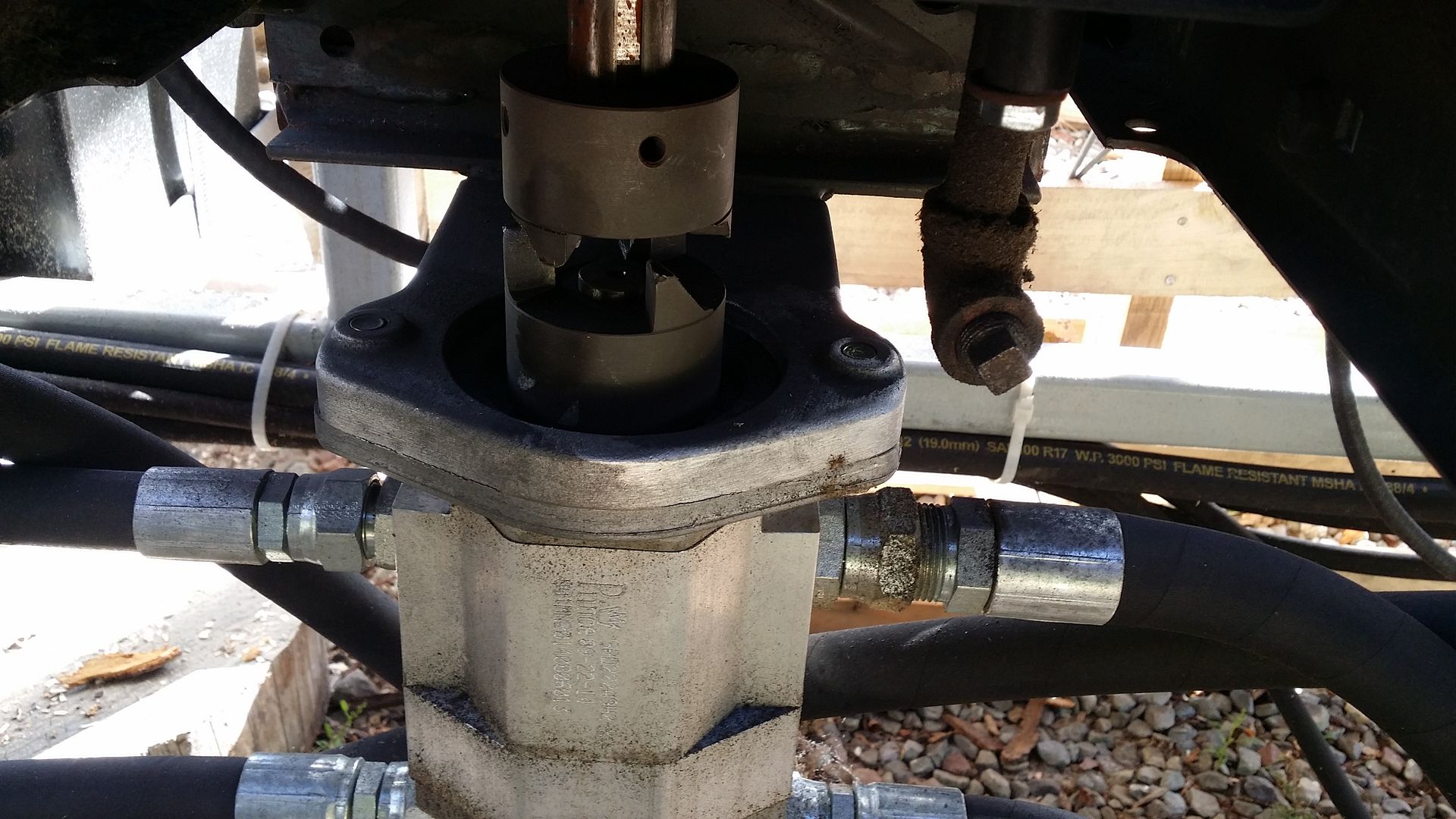

As mentioned, the oil cooler will need to be upgraded from 30k to an 85k or 90k BTU model. We still have issues maxing out the oil temp on 60 degree days. I think this issue will become more prevalent now that we have the tipper and two bags going. We have electrical capacity issues so adding an automotive alternator as mentioned before would help us out with the larger fan.

We seem to have issues with the bar oiler. The fuel pump we're using has issues keeping prime with the really thick bar oil from TSC. It did fine in the summer. Might be that the oil is thicker than what the pump can handle now that it is cooler. Saturday I used a turkey baster to remove most of the thick oil and then filled the tank with Sthil winter bar oil. Huge difference as far as consistency goes. It ran well on Sunday for me but I'm not sure if that is due to the lighter oil or the fact that it was 65 degrees. Time will tell.

We beefed up the bottom plates under the pusher plate to 3/8" steel. They bent slightly right after the install but have remained on there for at least 18 full cord. The old ones made of 1/4" steel would have to be replaced pretty much daily. We are pretty darned happy with that!

Note: We have NOT moved the splitter ram down as we were talking before.

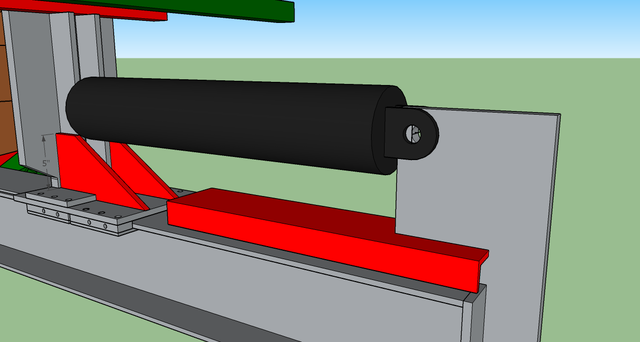

We are planning on adding a live deck this winter. As expected, the gravity log feed does not really work well. We'll likely use the circuit for the log stop to run the hydraulic motor.

Some of the logs we get in our loads are 20 feet long and our machine was only designed to handle 16 footers. The longer ones will usually balance okay on the rack if the butt end is towards the business end of the machine. However, when we drop them down into the infeed trough some of them will tip down out the back end to the ground. We're thinking about adding a 3 or 4 foot extension on the machine to better handle the longer logs.

Logs drop haphazardly into the splitter trough. Some logs drop right in place, hammer the splitter levers, and go. Others you need to wrestle with each piece as they drop. Not sure what to do there yet but we will probably try to do something.

That's pretty much it. Working pretty darned well as far as we're concerned.

![IMG_20150217_220514[1].jpg IMG_20150217_220514[1].jpg](https://www.tractorbynet.com/forums/data/attachments/377/377131-4a40b1ccdcf41dc0ed23e114a6152212.jpg)