Vigo327

Platinum Member

We'll see!!

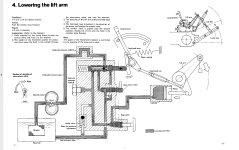

I believe that Vigo327 is saying that since the 3pt hitch is not going to be used at the same time as the backhoe is installed, then it is possible to use the 3pt hitch's internal circuit as a path for the backhoe fluid return flow. (backhoe fluid OUT).Huh ? Lol

No. Leave that valve as it is. It is the "stop/lock valve", a needle valve to "fluid lock" movement of the 3pt piston.This valve under the seat I believe locks the 3 pt so it won't move ? Should I use that

I'd remove just enough metal to get the bolts to slide in for now. It won't clamp all that well with half a washer worth of compressive force missing, but you want what you can get. Looks like it will probably need longer bolts, too. Metrics will fit tighter in the hole.I ran out of welding gas so I can't complete the front bracket just yet but the rear hooked up rather easy. I had to take the hitch off though. My only concern is I had to remove a bolt on each side to get the frame to slide on. Deciding if I want to remove the frame and grind that section away to get the bolts in ?

Yes, not the way I would normally do it - but I'm glad for your idea and think it is definitely worth a try.I don't think the missing bolt is intended to be part of securing the subframe so i would just notch out that part of the bracket that is interfering with the bolt. My .02.

Thanks rScotty for giving my hydraulics comments the benefit of the doubt. I'm sure im not doing the best job explaining my ideas, but you definitely 100% got what i meant.