I have been reading a series of posts about the rough ride of the GC SCUTS with interest, as my 2008 GC2400 certainly has the roughest ride of any of the 4 tractors here on the farm. Until those posts I had assumed it was because the little SCUT has the smallest diameter wheels and there is no long-travel seat springing as on all the other farm tractors. However, one fellow found making sure the tire pressure was no more than 15psi really helped. Well, I only got this little beast 3 years ago and had never checked the pressure, so while I was working on another tractor with a low tire, I thought I'd check the GC2400.I couldn't seem to unscrew the valve cap, and actually had to resort to pliers to get it started when SPLOOSH! I was sprayed with a dark amber/brown sticky substance! I jammed what appears to be a plastic plug back in the hole, but not before around a pint of that sweet sticky stuff was all over me, my tools, and the adjacent tractor. What the heck?

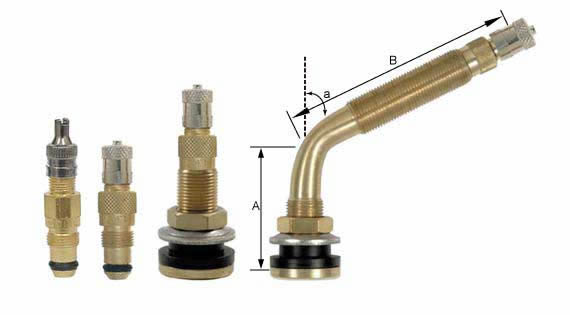

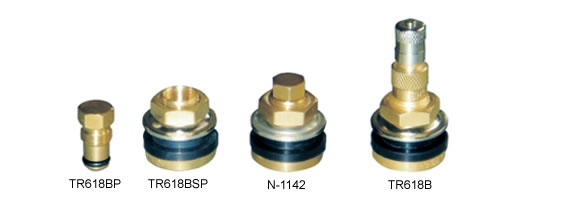

We use fluid filled tires on 2 of the other tractors, but I have used windshield washer fluid when I added it and always it was through a standard Schrader tire valve using an adapter. Checking pressure is done the same way. Was that beet juice? What is this fill point? Is that a plug used when a commercial dealer adds fluid? it was certainly new to me. I guess this helps explain the rough ride, too...

=Vic=

We use fluid filled tires on 2 of the other tractors, but I have used windshield washer fluid when I added it and always it was through a standard Schrader tire valve using an adapter. Checking pressure is done the same way. Was that beet juice? What is this fill point? Is that a plug used when a commercial dealer adds fluid? it was certainly new to me. I guess this helps explain the rough ride, too...

=Vic=