There's been a couple bridge threads in the last six months or so. Usually they take off with lots of pics. This one is struggling a little.

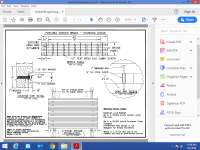

This was almost a DIY, but the contractor building our house gave me a killer price. I had an engineer develop the drawings and specs with trucks in mind (fire truck, triaxle dump trucks, etc.). In 1989 the rebar was around $1,100 IIRC. The bore is 16' and the footers are something like 9' down. All poured reinforced concrete. All sorts of trucks and equipment have used it. 3 or 4 years after we moved in we had a crew pave the driveway, and about 5 years ago we had the blacktop repaired and topped.

As part of the whole site design, the creek had a big elbow that curved around the bridge location that was removed to compensate for the bridge being placed in the flood plain. The nice part is the bridge was built on dry land. We straightened the creek to pass under the bridge after the bridge was completed. The clump tree behind the bridge was on the bank of the creek.

Between 0 and 6 times a year the driveway looks like the second picture for a couple hours max each occurrence. If you look closely you can just make out the edges of the curbs on the bridge. As long as you can see the curbs, the water is only 6-8" deep at the lowest part of the driveway surface and safe to travel.

Side note - I buried concrete-encased conduits beneath the new creek location while it was still dry land. This provides for easier replacement of the municipal water line, cable, phone and power if needed . Digging across a creek is probably a lot more complicated nowadays.