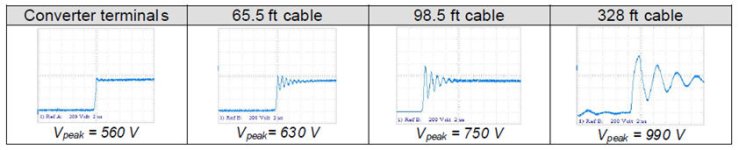

"Motors are rated to withstand voltage magnification caused by harmonic distortion of the motor current. However, when the same motor is connected to VFDs, the motor and its insulation can be subjected to a repetitive stresses from voltage pulses caused by harmonic distortion that can seriously damage the motor or its insulation rating degradation, causing catastrophic failure in a short period of time. Even if such failure does not happen quickly, the pulses will eventually degrade the system and reduce the potential lifespan of the motor. This is due, in part, to the odd-order voltage produced by a VFD, and not the typical sinusoidal wave that is normally provided from a power utility. As a result, when motors are connected to VFDs, they will experience repeating voltage pulses. Those voltage pulses may, under certain circumstances, be magnified as they reach the motor terminals. For example, in tests under actual operating conditions, a 460 volt motor supplied by voltage from a VFD has been empirically measured with pulses as high as 1200 volts, in contrast with the 620-660 volt level measured in the absence of magnification. "

This is why!!!

I have 1940's, 1950's, 1960's and newer three phase motors. I can't afford to replace them even if replacements were available. Some may have special frames specifically designed for the particular machine tool. I know it's 2016, again the machines are not even 1980.