Ductape

Elite Member

I would check where your relief is set first. Sometimes they are very conservative from the factory. You may get what you are looking for just by bringing the pressure up some. Making new lift cylinders sounds awful expensive.

I have a BX25 and I would be very hesitant about increasing the FEL lift capacity. When I carry something at the max my FEL can lift (e.g., wet sand), I can really feel the strain on the front end components, and I drive VERY slowly and carefully. I agree that the max is FEL lift capacity is inconveniently low on these things compared to other similarly priced brands, but I also do not want to bugger up my front drive train, wheels, bearings, axle, etc..

If you make a change please advise exactly what you did.

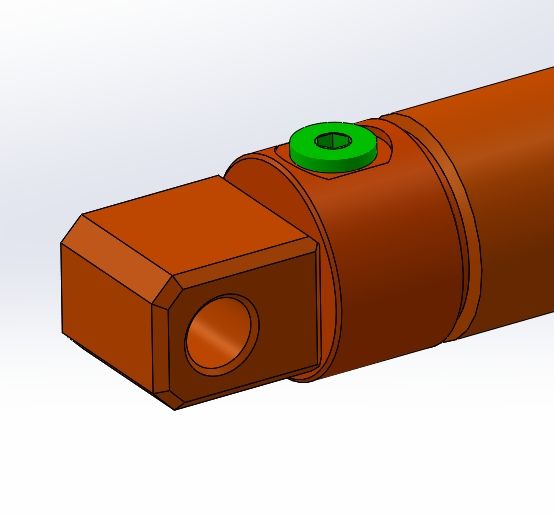

I would suggest that a knowledgeable operator would have

no problems. I would suggest bumping up the cylinder size

alone to start and wee what you think. I would like a Model Number

for said cylinder if you have it nailed down.

Ah HA! Another CAD man! I love AutoCAD 2D myself.

But....why not just cut both OE ends off the OE cylinder

and weld on to the new cylinder?