Verticaltrx

Veteran Member

- Joined

- Dec 30, 2009

- Messages

- 1,908

- Location

- VA

- Tractor

- Kubota B3200/L2501/SVL65-2/U35-4, IH 454/656, Ford NAA, Case 1845C/480E/450C LGP

Thought some of yall might be interested in the 628 CadDigger I built. I wanted a small backhoe for small trenching jobs, light excavation, and other jobs I encounter in my agricultural construction business and the CadDiggers seemed to fit the bill. At the time I didn't have my B3200, and I wouldn't have spent $7000-8000 for a backhoe attachment anyways. Plus with the 628 I can tow it quickly to a small job with my Tacoma without bringing one of my bigger trucks and trailers.

I built this in my farm shop using basic tools such as a chop saw, drill press, 4.5" grinder, etc. Welding was done with my Lincoln SP175-T MIG welder (.035 flux core) and Lincoln 225AC stick welder (1/8" 7018.)

Here's the main frame, hydraulic tank, stabilizer assy.

Next was the main swing assy. (prior to welding)

Main boom

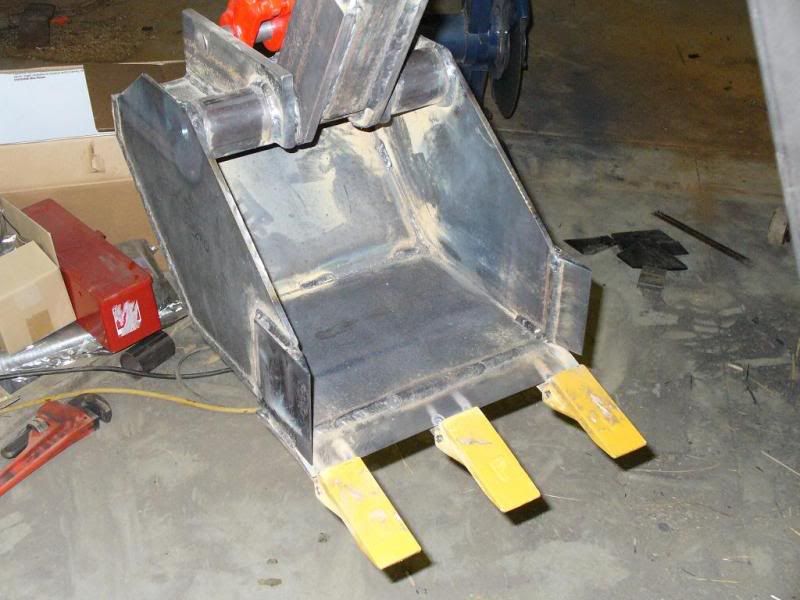

This is the shell of the 12" bucket I made

More forthcoming...

I built this in my farm shop using basic tools such as a chop saw, drill press, 4.5" grinder, etc. Welding was done with my Lincoln SP175-T MIG welder (.035 flux core) and Lincoln 225AC stick welder (1/8" 7018.)

Here's the main frame, hydraulic tank, stabilizer assy.

Next was the main swing assy. (prior to welding)

Main boom

This is the shell of the 12" bucket I made

More forthcoming...