thoner7

Silver Member

- Joined

- Feb 26, 2019

- Messages

- 149

- Tractor

- to-20 Ferguson and Kubota m5400 with Quickie loader

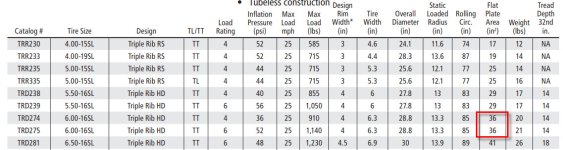

I'm trying to calculate out the PSI of pressure on the ground. So by taking the tire width, and multiple it by the length of the tire that actually hits the ground. What should I use for that dimension?

Like a 14.9-24 rear would be 14.9" wide x ??? =

Or a 6-16 from would be 6" wide x ??? =

Like a 14.9-24 rear would be 14.9" wide x ??? =

Or a 6-16 from would be 6" wide x ??? =