Bansil

Gold Member

- Joined

- Mar 14, 2016

- Messages

- 447

- Location

- State Of Franklin

- Tractor

- 1967 Ford 5000 w/FEL(sold), 1950 Farmall Super A for the wife to drive around (needs fixed) 2024 Kubota B2601 FEL & BH

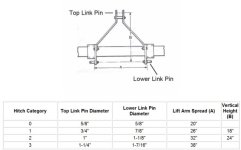

I can run 2 and 1, tractor came with a couple cat 1 drawbars (like TSC sells)

What tounge type weight, pull weights is typical limits of them? Basically shearing off ends.

Plan on making 2" rec hitch this weekend, for under 6000 lbs vehicle's etc, should be fine

Other project is a 850/1000 pound ballast weight 3 pt setup...

Should i step up to the bigger cat 2 drawbar?

Plan is concrete barrel

Tia

What tounge type weight, pull weights is typical limits of them? Basically shearing off ends.

Plan on making 2" rec hitch this weekend, for under 6000 lbs vehicle's etc, should be fine

Other project is a 850/1000 pound ballast weight 3 pt setup...

Should i step up to the bigger cat 2 drawbar?

Plan is concrete barrel

Tia