sd455dan

Super Member

- Joined

- Oct 23, 2012

- Messages

- 6,351

- Location

- North Idaho

- Tractor

- Rhino 554, Ford 550 TLB (JD X500, MTD, Gilson riding mowers) Ford 3000-Sold

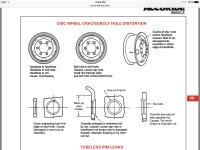

My 2010 JD 2720 had a new twist yesterday that I have never seen the likes of.

I was working a small pile of dirt from one spot to another when I notices a wobble

on my left front wheel. Stopped and set the load down to inspect, and could not

believe what I was looking at. The rim had split in several places fronm the lug nuts

outwards, and around the outer edges if the inner rim plate. Has anyone seen this before ?

And, what could be the cause of such a failure???

Has anyone seen this before ?

Yes

a few posts concerning a chinese built Luzhong tractor some time ago in the chinese tractor forum.