OP

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

OK, I kinda buried the numbers in my usual blather

Hoe cylinders -

2 Stabilizers

2 Swing cyls

2 Boom cyls (one each side)

1 Stick(dipper) cyl

1 Bucket cyl

Loader cylinders -

2 Lift cyls

2 Curl cyls

1 Auto level cyl. (Oh, and don't ask me exactly how it works, maybe I'll know when I'm done with ALL of 'em )

)

Here's a pic from the brush bucket build, and a marked up version -

Clear as mud, right??!? Steve

Oops, forgot your last question;

"The last picture is the rod with seals on the end, how do they come off, I'm assuming you're going to change everything?"

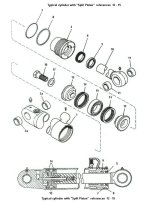

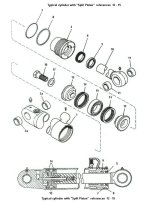

Yup, the gland has an external wiper seal, an internal wiper couple O rings and a "slider" thingy - the piston on these older cases is a split (2 piece) with a center piece and several "squished together" seals on both sides, with 2 recessed washers surrounding those. 1-1/8" fine thread bolt goes in the back of the rod (the straight end), and everything goes back on the rod and that bolt torqued to 450 lbs, THEN it gets shoved back into the barrel, tighten up the gland, put a new lock screw between gland and cylinder body (barrel) - here's an exploded view; #5 is the EXTERNAL wiper, 6 is the INTERNAL wiper/pressure seal, 3 is the gland, #8 and 7 are the O ring and backing ring that go right behind the outer face of the gland - Then # 12 and 13 are the "squishing washers" (NOT part of a kit), 14 and 15 are part of the kit, and 16 and 17 are the 450 lb. bolt/washer.

The outer end (gland nut end) is belled out, and the previous cylinders I did I wrapped the rod seals with some thin aluminum flashing til they started into the bell; worked well. You still need a heavy comealong or something to force things back together, and a good slather of hyd. oil if you actually want it to MOVE Hope that helps... Steve

Hope that helps... Steve

Oh, BTW - that gland nut is an absolute ***** to clean out after the "hot wrench" treatment, but so's LIFE

Hoe cylinders -

2 Stabilizers

2 Swing cyls

2 Boom cyls (one each side)

1 Stick(dipper) cyl

1 Bucket cyl

Loader cylinders -

2 Lift cyls

2 Curl cyls

1 Auto level cyl. (Oh, and don't ask me exactly how it works, maybe I'll know when I'm done with ALL of 'em

Here's a pic from the brush bucket build, and a marked up version -

Clear as mud, right??!? Steve

Oops, forgot your last question;

"The last picture is the rod with seals on the end, how do they come off, I'm assuming you're going to change everything?"

Yup, the gland has an external wiper seal, an internal wiper couple O rings and a "slider" thingy - the piston on these older cases is a split (2 piece) with a center piece and several "squished together" seals on both sides, with 2 recessed washers surrounding those. 1-1/8" fine thread bolt goes in the back of the rod (the straight end), and everything goes back on the rod and that bolt torqued to 450 lbs, THEN it gets shoved back into the barrel, tighten up the gland, put a new lock screw between gland and cylinder body (barrel) - here's an exploded view; #5 is the EXTERNAL wiper, 6 is the INTERNAL wiper/pressure seal, 3 is the gland, #8 and 7 are the O ring and backing ring that go right behind the outer face of the gland - Then # 12 and 13 are the "squishing washers" (NOT part of a kit), 14 and 15 are part of the kit, and 16 and 17 are the 450 lb. bolt/washer.

The outer end (gland nut end) is belled out, and the previous cylinders I did I wrapped the rod seals with some thin aluminum flashing til they started into the bell; worked well. You still need a heavy comealong or something to force things back together, and a good slather of hyd. oil if you actually want it to MOVE

Oh, BTW - that gland nut is an absolute ***** to clean out after the "hot wrench" treatment, but so's LIFE

Last edited: