StevenPaul

Silver Member

- Joined

- Sep 9, 2005

- Messages

- 133

- Location

- Anderson County, SC

- Tractor

- John Deere 2010 (Kranky), JD 4500

Hello Y'all!

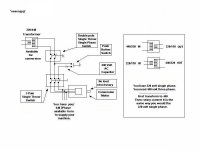

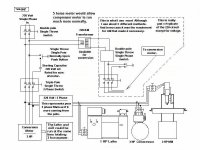

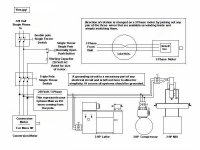

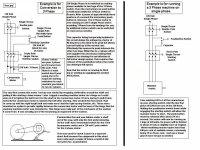

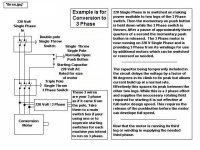

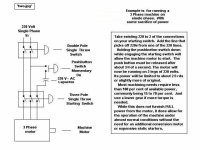

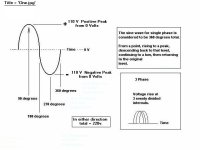

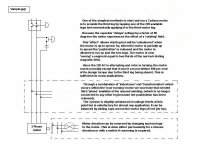

Don't know if this goes in this forum, but I'll be using this rig to "build it yourself" on some other projects. My wife bought and 3 teenagers got(lifted) this drill press from a yard sale for $75. It's a beast! It can run on 440. I don't know what voltage the previous owners had it on. I eventually want to run it at 220/230 in my shop that we will be building later but for now, I need it as 110/120. Can someone help me on how to wire this thing? It's got some schmatics in the cover but I can't make heads or tales of them. I know some about basic house wiring (I just finished wiring my "temp" shop) but this thing is confusing. It says something about taking a wire from L2 to L3 if going single phase. Check the pictures out and if ya can help, awesome! if not, where can I go to get some help?

thanks in advance!

Steve

Don't know if this goes in this forum, but I'll be using this rig to "build it yourself" on some other projects. My wife bought and 3 teenagers got(lifted) this drill press from a yard sale for $75. It's a beast! It can run on 440. I don't know what voltage the previous owners had it on. I eventually want to run it at 220/230 in my shop that we will be building later but for now, I need it as 110/120. Can someone help me on how to wire this thing? It's got some schmatics in the cover but I can't make heads or tales of them. I know some about basic house wiring (I just finished wiring my "temp" shop) but this thing is confusing. It says something about taking a wire from L2 to L3 if going single phase. Check the pictures out and if ya can help, awesome! if not, where can I go to get some help?

thanks in advance!

Steve