Phil Timmons

Silver Member

- Joined

- Mar 18, 2008

- Messages

- 111

Looking for concept reviews on basic "Big Picture" details for Electric driven shop-built rototiller-ing.

Typical Range will likely be from 2 foot width minimum (about 5 to 10 HP (?) ) up to around 10 foot width maximum (25 to 50 HP (?)).

Or maybe modules that hook together to create various widths.

Motors probably 480V Three Phase, with VFD (Variable Speed Drive) controls.

Here are some of the details for comments or reviews (or anything else you see fit):

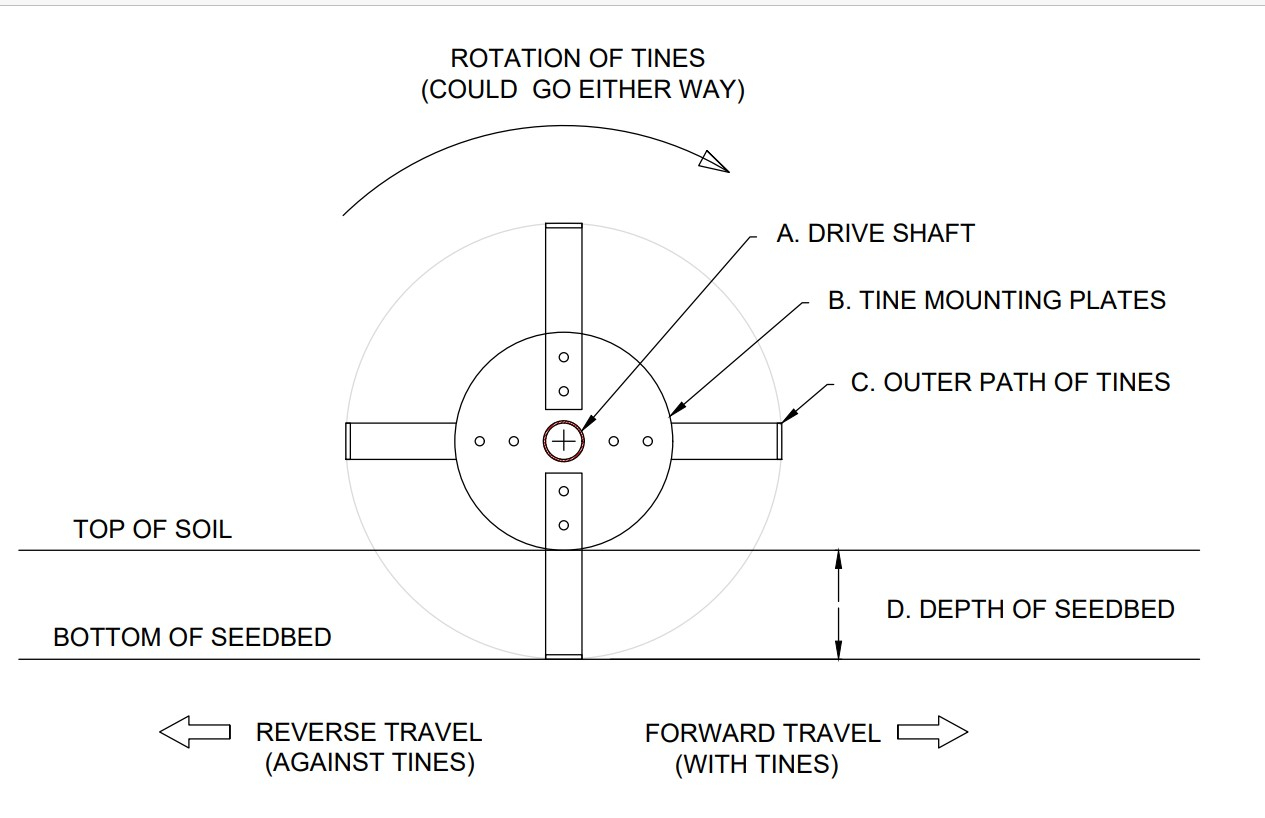

(Letters below are intended to match call-outs on the sketches).

A. Drive Shaft -- starting with 2" (2-3/8 external) Pipe. Strong enough? Too big? Solid is better?

B. Tine Mounting Plates -- 12" Diameter? 1/4" Plate? Too big, too much, what else?

C. Tine Length -- Create 24" sweep diameter? Too much, not enough?

D. Seed Bed Depth -- From "C" and "B" if 24" and 12" -- this gives a seed bed depth of 6" Good? need deeper?

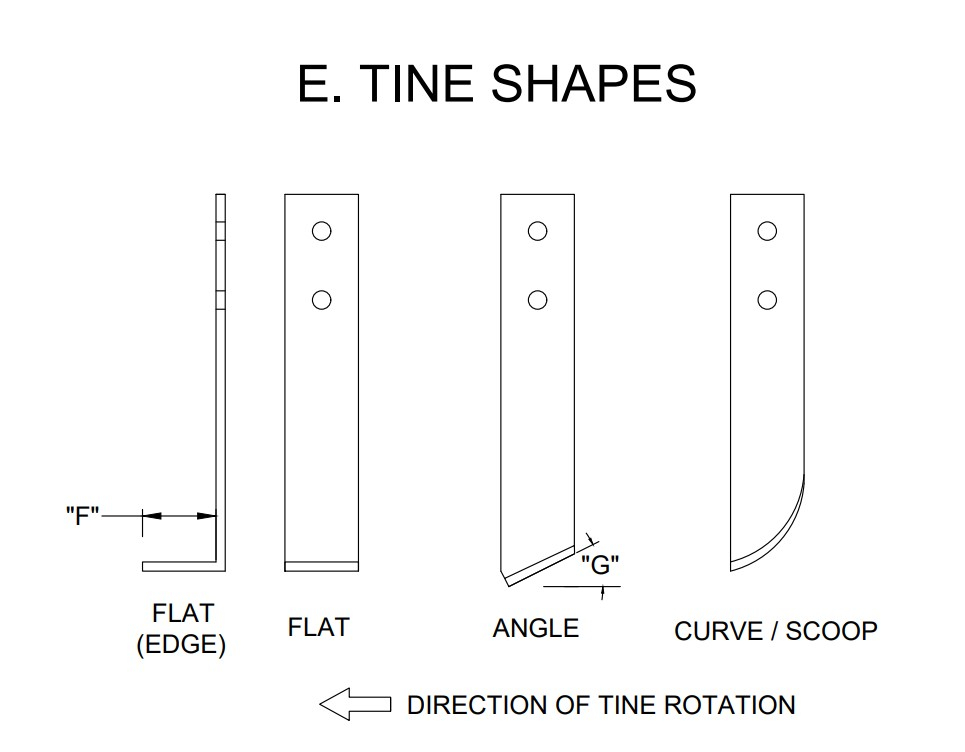

E. Tine Shape -- Flat Bend? Angle Bend? Scoop or Rounded?

F. Bend Length on Tine? 2" (?)

G. Angle for Angle Bend Tine (?) 30 Degrees?

RPM(s) -- typical Tractor 540 RPM PTOs are generally taken down to 200 RPM for the Tine Drive Shaft. This creates a set edge (of Tine) travel speed. Any thoughts on the optimal Tine edge speed through the soil?

THANKS!

Typical Range will likely be from 2 foot width minimum (about 5 to 10 HP (?) ) up to around 10 foot width maximum (25 to 50 HP (?)).

Or maybe modules that hook together to create various widths.

Motors probably 480V Three Phase, with VFD (Variable Speed Drive) controls.

Here are some of the details for comments or reviews (or anything else you see fit):

(Letters below are intended to match call-outs on the sketches).

A. Drive Shaft -- starting with 2" (2-3/8 external) Pipe. Strong enough? Too big? Solid is better?

B. Tine Mounting Plates -- 12" Diameter? 1/4" Plate? Too big, too much, what else?

C. Tine Length -- Create 24" sweep diameter? Too much, not enough?

D. Seed Bed Depth -- From "C" and "B" if 24" and 12" -- this gives a seed bed depth of 6" Good? need deeper?

E. Tine Shape -- Flat Bend? Angle Bend? Scoop or Rounded?

F. Bend Length on Tine? 2" (?)

G. Angle for Angle Bend Tine (?) 30 Degrees?

RPM(s) -- typical Tractor 540 RPM PTOs are generally taken down to 200 RPM for the Tine Drive Shaft. This creates a set edge (of Tine) travel speed. Any thoughts on the optimal Tine edge speed through the soil?

THANKS!