Phil Timmons

Silver Member

- Joined

- Mar 18, 2008

- Messages

- 111

NOTE to MODS: The following images are from a Yanmar Operator's Manual. I think this is considered "Fair Use," as we are discussing the various technical merits of equipment -- and not re-publishing documents. If this a violation of TractorByNet TOS, please delete. This full manual is also directly available from Yanmar, as a download PDF at https://www.yanmar.com/media/en_vn/2016/operationmanual/manual_RH170_RH190_en.pdf

==============================

Looking at some other samples . . . .

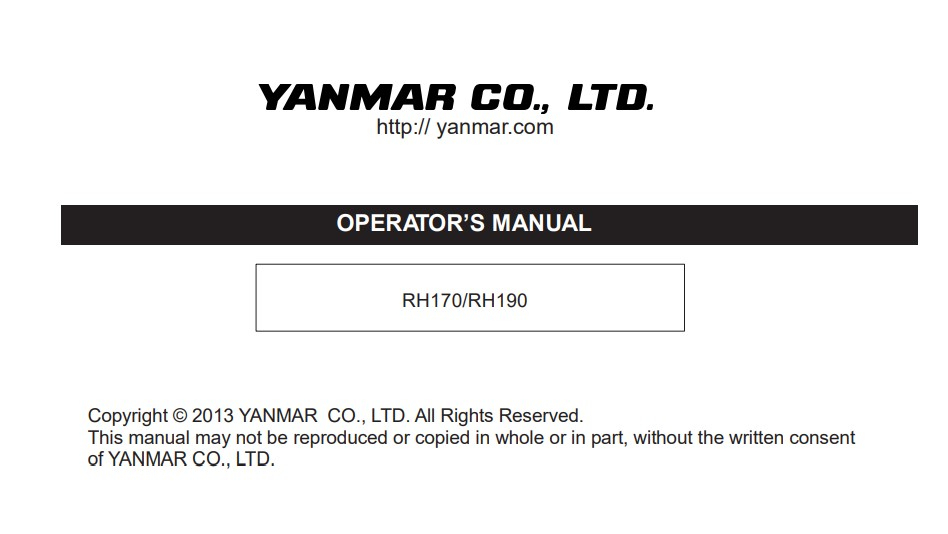

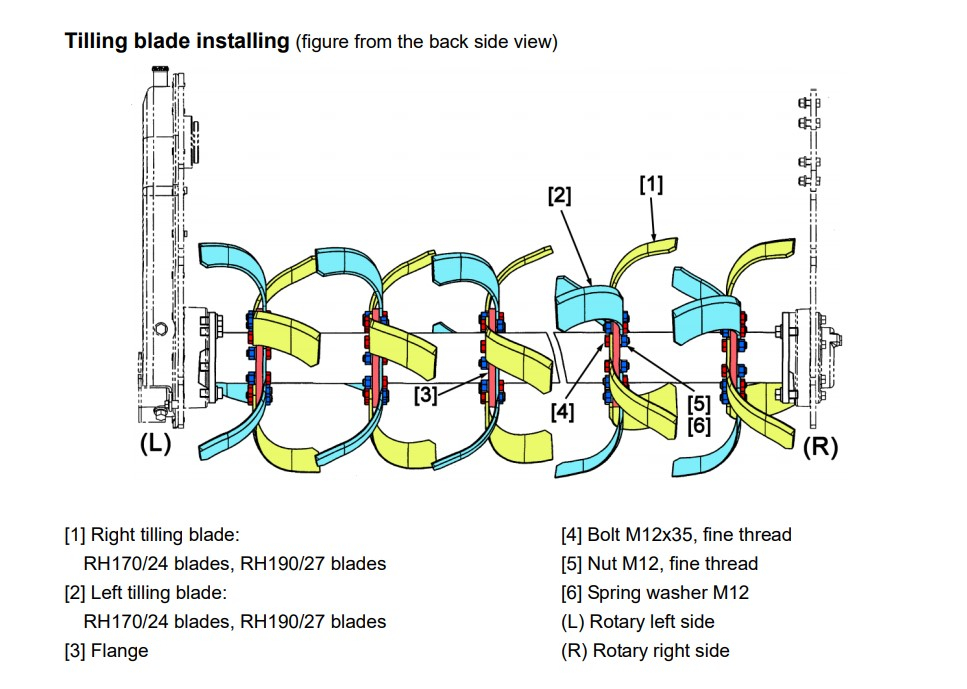

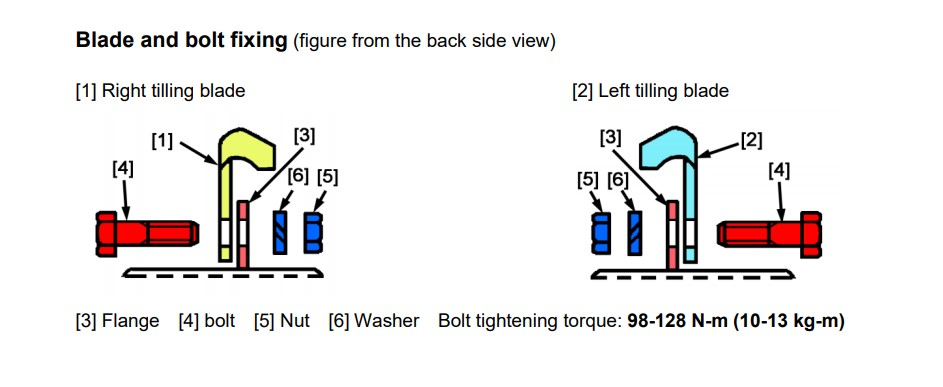

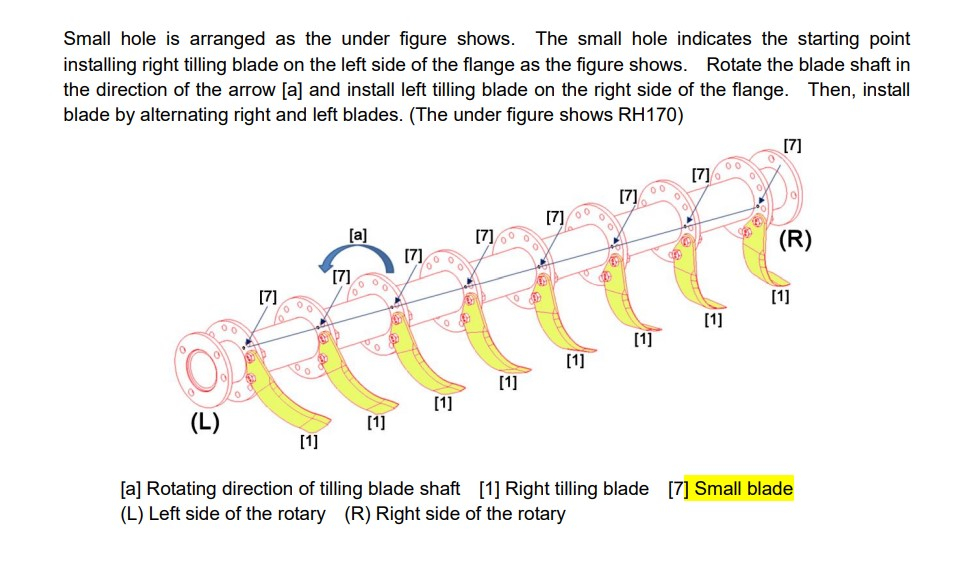

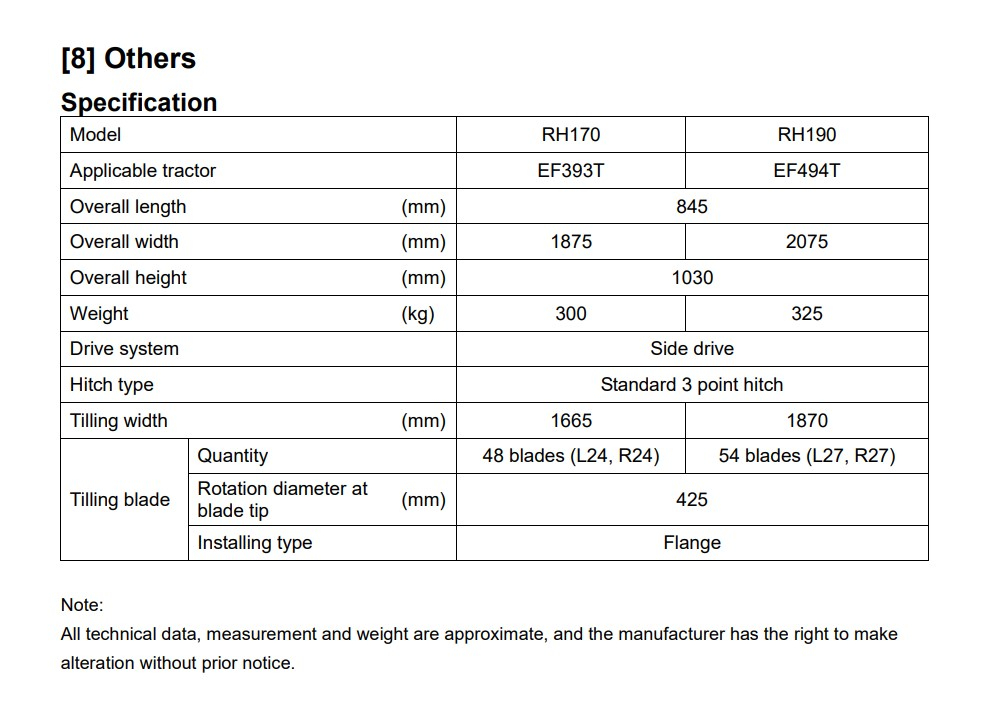

Images below show the details of a Yanmar 6 tine (as opposed to 4 Tine, like most of this discussion) per Mounting Plate Rototiller. It is interesting in that it appears to have a larger diameter mounting plate (allowing deeper soil penetration), and a method of aligning the various tine plate mounting with an index "small hole" method.

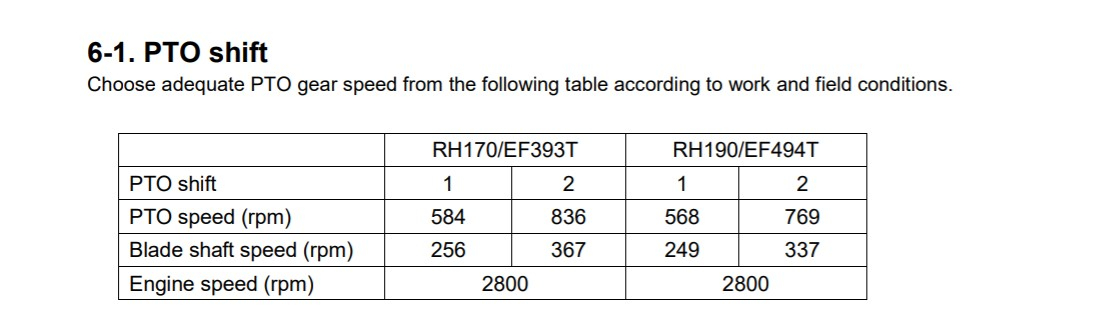

It is also showing higher RPM on both the PTO and final shaft drive -- maybe making this easier for Electric Motor use.

=============

================

=================

====================

===================

==================

==============================

Looking at some other samples . . . .

Images below show the details of a Yanmar 6 tine (as opposed to 4 Tine, like most of this discussion) per Mounting Plate Rototiller. It is interesting in that it appears to have a larger diameter mounting plate (allowing deeper soil penetration), and a method of aligning the various tine plate mounting with an index "small hole" method.

It is also showing higher RPM on both the PTO and final shaft drive -- maybe making this easier for Electric Motor use.

=============

================

=================

====================

===================

==================