You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electric selector valve

- Thread starter davesisk

- Start date

- Views: 10105

More options

Who Replied?

/ Electric selector valve

#41

MossRoad

Super Moderator

- Joined

- Aug 31, 2001

- Messages

- 66,851

- Location

- South Bend, Indiana (near)

- Tractor

- Power Trac PT425 2001 Model Year

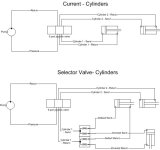

Nice diagram... thanks!

Phred

Veteran Member

Dave,

Great job. Looks good.

A few questions:

1) All your cylinders are double acting? So if we look at your “current” diagram, which appears to be the way the machine came, when you hit the lever to say raise the loader pressure is applied to the “send” line. At some point it will raise all the way up and pressure will be at the max limited by the tractor.

If you move the lever to “down” the tractor applies pressure to the “return” line and the cylinder goes down. I don’t think it’s just the weight since you can pickup the front end of your tractor by continuing to apply down force when the bucket contacts the ground?

So all this means that the pressure is actually applied in both directions depending on how you move the lever. Therefore, your selector valve must be by directional? In other words the terms “send” and “return” are meaningless since it depends on how you hit the lever? Am I missing something?

Since it works I guess this means the selector valve does not care which one is which. You could switch the “send” and “return” lines and it would still work?

2) With your new selector valve can you switch between the two cylinder loads even when they are under pressure?

3) Could you use a 12V rocker switch to select between the two loads? For example if you had a hydraulic auger on a loader. The bucket tilt cylinders or the auger could be run depending on the position of the rocker switch.

The reason for all the questions is I would like to do the same…. On a little bigger scale (12 GPM). I have two remotes which currently run the up and down on a loader and bucket tilt. It would be great to use your ideas to accomplish this.

The dealer wants $500 for a third remote /forums/images/graemlins/crazy.gif

Great job. Looks good.

A few questions:

1) All your cylinders are double acting? So if we look at your “current” diagram, which appears to be the way the machine came, when you hit the lever to say raise the loader pressure is applied to the “send” line. At some point it will raise all the way up and pressure will be at the max limited by the tractor.

If you move the lever to “down” the tractor applies pressure to the “return” line and the cylinder goes down. I don’t think it’s just the weight since you can pickup the front end of your tractor by continuing to apply down force when the bucket contacts the ground?

So all this means that the pressure is actually applied in both directions depending on how you move the lever. Therefore, your selector valve must be by directional? In other words the terms “send” and “return” are meaningless since it depends on how you hit the lever? Am I missing something?

Since it works I guess this means the selector valve does not care which one is which. You could switch the “send” and “return” lines and it would still work?

2) With your new selector valve can you switch between the two cylinder loads even when they are under pressure?

3) Could you use a 12V rocker switch to select between the two loads? For example if you had a hydraulic auger on a loader. The bucket tilt cylinders or the auger could be run depending on the position of the rocker switch.

The reason for all the questions is I would like to do the same…. On a little bigger scale (12 GPM). I have two remotes which currently run the up and down on a loader and bucket tilt. It would be great to use your ideas to accomplish this.

The dealer wants $500 for a third remote /forums/images/graemlins/crazy.gif

Hi Phred:

Yes, all the cylinders are double-acting, so "yes" the presssure becomes return and the return becomes pressure. The selector valve just makes that path available, it doesn't care which direction the fluid is actually flowing. I labelled them "send" and "return" just to be able to keep it straight which side plugs into what.

Yes you should be able to do this with 12 gpm easily. And I don't see any reason it wouldn't work with a rocker switch as well as a pushbutton. If it's going to be such that you divert it for "a while" rather than just momentarily, then I'd save myself some money and just get a manual diverter valve rather than an electric diverter valve (unless the hoses are just impossible to run that distance, or something).

You can switch under pressure, although I think the docs recommend that you not switch while fluid is actually flowing. Of course, that's hard not to do with pushbutton...takes a bit of coordination!

HTH,

Dave

Yes, all the cylinders are double-acting, so "yes" the presssure becomes return and the return becomes pressure. The selector valve just makes that path available, it doesn't care which direction the fluid is actually flowing. I labelled them "send" and "return" just to be able to keep it straight which side plugs into what.

Yes you should be able to do this with 12 gpm easily. And I don't see any reason it wouldn't work with a rocker switch as well as a pushbutton. If it's going to be such that you divert it for "a while" rather than just momentarily, then I'd save myself some money and just get a manual diverter valve rather than an electric diverter valve (unless the hoses are just impossible to run that distance, or something).

You can switch under pressure, although I think the docs recommend that you not switch while fluid is actually flowing. Of course, that's hard not to do with pushbutton...takes a bit of coordination!

HTH,

Dave

Charlie_Iliff

Veteran Member

- Joined

- Jun 13, 2001

- Messages

- 1,890

- Location

- Arnold, MD

- Tractor

- Power Trac PT1845, John Deere 2240, John Deere 950, John Deere 755, Jacobsen Turf Cat II

<font color="red"> You can switch under pressure, although I think the docs recommend that you not switch while fluid is actually flowing. </font>

Phred:

Dave's undoubtedly right that there is an instruction somewhere not to switch under certain circumstances, but I got mine with no documentation and have routinely pressed the button while the joystick was hard over, with no adverse effects so far.

A double pole momentary contact rocker won't really work, because the path is to one cylinder when the diverter is not activated and to the other when the 12 volt is turned on. Rather than a momentary switch, you could certainly use an on-off switch that clicks to the ON position and stays there until turned off. (Could be rocker, toggle or whatever, but needs only to be single pole ON-OFF)

If you go this route, be careful to economise as Dave did, or you'll be approaching the $500 cost to install a system which may not be quite as good for your purposes as the second remote. You need to think through exactly how each needed function will work with each of the two systems and decide what's best for you.

For such things as an auger, there are electric solenoid valves to turn on a single line rather than diverting a two-line circuit the way Dave and I did. If you know where to attach the pressure and return lines at the pump and tank, that may be another - and possibly better - way to go.

Hope I didn't confuse the issue. But, sometimes that's what I do best. /forums/images/graemlins/tongue.gif

Phred:

Dave's undoubtedly right that there is an instruction somewhere not to switch under certain circumstances, but I got mine with no documentation and have routinely pressed the button while the joystick was hard over, with no adverse effects so far.

A double pole momentary contact rocker won't really work, because the path is to one cylinder when the diverter is not activated and to the other when the 12 volt is turned on. Rather than a momentary switch, you could certainly use an on-off switch that clicks to the ON position and stays there until turned off. (Could be rocker, toggle or whatever, but needs only to be single pole ON-OFF)

If you go this route, be careful to economise as Dave did, or you'll be approaching the $500 cost to install a system which may not be quite as good for your purposes as the second remote. You need to think through exactly how each needed function will work with each of the two systems and decide what's best for you.

For such things as an auger, there are electric solenoid valves to turn on a single line rather than diverting a two-line circuit the way Dave and I did. If you know where to attach the pressure and return lines at the pump and tank, that may be another - and possibly better - way to go.

Hope I didn't confuse the issue. But, sometimes that's what I do best. /forums/images/graemlins/tongue.gif

Phred

Veteran Member

Thanks guys.

I thought that was the case but just wanted to be sure. Some of the hydraulic valves appear to care a great deal about the direction so that is why I was curious.

The reason I want to go electric is it’s a cab tractor so running hydro lines into the cab is not a good option. Electric is a piece of cake.

Your right about the $500 for third remote, if it was just $500. But that’s the parts only. Haul to shop, labor, and lack of use of the machine would be additional.

Course I could probably get the parts myself and do the work but the dealers make that hard. Also you would still need the lines to plumb up to the loader, fittings, etc..

So its really more like $500 versus the ~$150 for the diverter valve, since they will both need the additional fittings, hoses, etc…

</font><font color="blue" class="small">( If you know where to attach the pressure and return lines at the pump and tank, that may be another - and possibly better - way to go.)</font>

They way a lot tractors work you don’t have easy access to those individual lines. I have one joy stick which controls two sets of remotes. That’s two sets of send and receive lines, four total lines. The diverter value(s) will allow me to use toggle switches to control more than two loads. The cab tractor also already has a few extra spots for rocker switches close to the joy stick so it would be easy to fish a wire and be in business.

The rocker switch will work better for me since I can use the joy stick to control the bucket tilt and lift cylinders on the loader connected up to a bobcat auger to position the auger. Then Flip a rocker that switches the bucket tilt hydro lines to the auger. You can now use the joystick to run the auger and apply down force with the lift cylinders as needed.

Fred

I thought that was the case but just wanted to be sure. Some of the hydraulic valves appear to care a great deal about the direction so that is why I was curious.

The reason I want to go electric is it’s a cab tractor so running hydro lines into the cab is not a good option. Electric is a piece of cake.

Your right about the $500 for third remote, if it was just $500. But that’s the parts only. Haul to shop, labor, and lack of use of the machine would be additional.

Course I could probably get the parts myself and do the work but the dealers make that hard. Also you would still need the lines to plumb up to the loader, fittings, etc..

So its really more like $500 versus the ~$150 for the diverter valve, since they will both need the additional fittings, hoses, etc…

</font><font color="blue" class="small">( If you know where to attach the pressure and return lines at the pump and tank, that may be another - and possibly better - way to go.)</font>

They way a lot tractors work you don’t have easy access to those individual lines. I have one joy stick which controls two sets of remotes. That’s two sets of send and receive lines, four total lines. The diverter value(s) will allow me to use toggle switches to control more than two loads. The cab tractor also already has a few extra spots for rocker switches close to the joy stick so it would be easy to fish a wire and be in business.

The rocker switch will work better for me since I can use the joy stick to control the bucket tilt and lift cylinders on the loader connected up to a bobcat auger to position the auger. Then Flip a rocker that switches the bucket tilt hydro lines to the auger. You can now use the joystick to run the auger and apply down force with the lift cylinders as needed.

Fred

Here are some similar links:

- Replies

- 14

- Views

- 4K