Shield Arc

Super Member

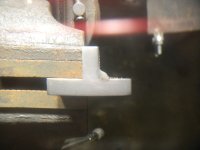

I have never done this before. When doing the testing of Roadhunter's new Everlast 120-volt Mig welder over on Welding Web. I was ask to do some etch testing. This was quite a learning experience for me:laughing:. I first tried naval jelly, then battery acid. The results were less than stellar!:thumbdown: So I ordered some phosphoric acid off ebay. It arrived yesterday. I cleaned up the fillet welds done by the Everlast 120-volt Mig run at max settings on 3/8-inch thick flatbar . And the one I did with my V350-Pro run at 29-volts, 224-amps.

First two pictures are the Everlast welds. First one is with the acid still on it. The second picture is with the acid wiped off. Not sure you can see it in this picture, the weld didn't even bite into the corner of the two plates:shocked:. Third picture is the weld made with the Lincoln V350-Pro,

First two pictures are the Everlast welds. First one is with the acid still on it. The second picture is with the acid wiped off. Not sure you can see it in this picture, the weld didn't even bite into the corner of the two plates:shocked:. Third picture is the weld made with the Lincoln V350-Pro,