You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Etching welds.

- Thread starter Shield Arc

- Start date

- Views: 10144

More options

Who Replied?

/ Etching welds.

#31

Shield Arc

Super Member

Oh yeah she is a sweet machine. These inverters just amaze me with the control they have over the puddle. That weld was run with 0.0 on the pinch / arc force. Need to run a fillet weld with it, and set the pinch / arc force up more and see if that gives any more penetration.

Shield Arc

Super Member

Looking good. :thumbsup:

Now that you've got your etching skills perfected, you'll probably be etching anything and everything you've done in the past, that you can find.

You might even need to order a couple more bottles of that etching elixir. :cool2:

Now that you've got your etching skills perfected, you'll probably be etching anything and everything you've done in the past, that you can find.

You might even need to order a couple more bottles of that etching elixir. :cool2:

dragoneggs

Super Star Member

- Joined

- Jun 9, 2013

- Messages

- 14,548

- Location

- Seabeck, Washington

- Tractor

- Kubota BX-25D, Kubota Z122RKW-42

Hey SA, I doubt you have the weld you did with my 211 on 3/4" Tee fully cranked but if you do, I wonder what kind of penetration you got?

Shield Arc

Super Member

Oh boy, I'll have to look. It might have gone to Navy City Metals. I took a load there not to long ago.

Shield Arc

Super Member

Welp, I couldn't find it , it must have went to the scrap yard. Would have been interesting to see how much penetration it got.

, it must have went to the scrap yard. Would have been interesting to see how much penetration it got.

Gary Fowler

Super Star Member

- Joined

- Jun 23, 2008

- Messages

- 11,998

- Location

- Bismarck Arkansas

- Tractor

- 2009 Kubota RTV 900, 2009 Kubota B26 TLB & 2010 model LS P7010

Etching shows the weld profile but not the strength of the weld metal. There is no substitute for a proper bend test for determining quality of weld metal, not even an X-ray will prove the welders and welding rod ability like a bend test will. That is why even after all macro-graphs, etchings, xray testing etc have been done on a welding PROCEDURE qualification, a bend test is the acceptance standard.Very Interesting. Better than a bend test.

I have seen beautiful welds that failed the ASME IX bend test procedure.

Sodo

Elite Member

- Joined

- Apr 21, 2012

- Messages

- 3,311

- Location

- Cascade Mtns of WA state

- Tractor

- Kubota B-series & Mini Excavator

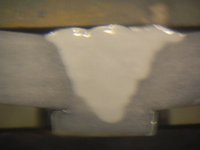

Here's a natural etch, using water.

I welded the ball onto this simple pin hitch. It's for a neighbor's ATV, used mostly to move his firewood splitter around. He wouldn't go on the highway with it, this is an ATV unit.

I welded the ball on, then realized that the ball was too close to the hitch so had to move the hitch pin hole. I cut 3/4" off the end, cut in the middle and welded it back in with 1/8" gaps to get a full inch.

I welded the ball onto this simple pin hitch. It's for a neighbor's ATV, used mostly to move his firewood splitter around. He wouldn't go on the highway with it, this is an ATV unit.

I welded the ball on, then realized that the ball was too close to the hitch so had to move the hitch pin hole. I cut 3/4" off the end, cut in the middle and welded it back in with 1/8" gaps to get a full inch.

Attachments

Here are some similar links:

- Replies

- 15

- Views

- 12K