wade23454

Member

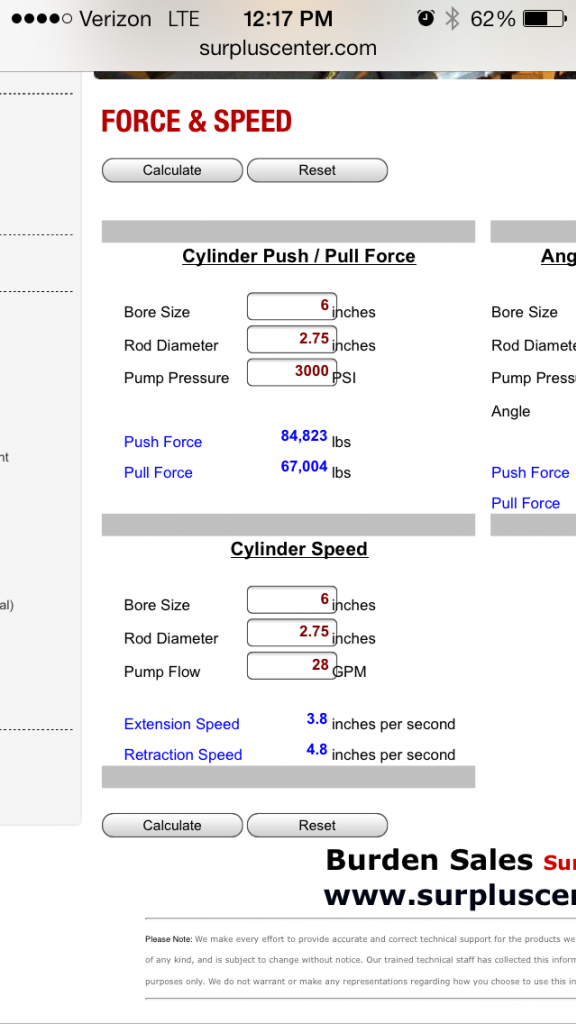

Your pump size is way too big and will result in a 13 ton max output. If you use a 13GPM pump, you'll get 30 tons of force.

My math should be verified by an expert, lol.

Edit: Guess you can get two stage pumps that give the speed/force combination you are looking for.

http://www.ebay.com/itm/28-GPM-2-ST...ics-Wood-Splitter-/271303389853#ht_382wt_1126

My math should be verified by an expert, lol.

Edit: Guess you can get two stage pumps that give the speed/force combination you are looking for.

http://www.ebay.com/itm/28-GPM-2-ST...ics-Wood-Splitter-/271303389853#ht_382wt_1126