JimMc

Platinum Member

I don't think it's being picky at all. The fact is that there is nothing on a FC deck that is stamped. Even the parts that are formed are produced by press brake not stamping. It's not that Sicma isn't capable of stamping, but to keep costs down, they necessarily chose different technologies to produce that machine. No reflection on the quality of the finished product at all. It's a good machine and the deck is quite durable. However, it is not fair to attempt to sell a product on features it doesn't have.

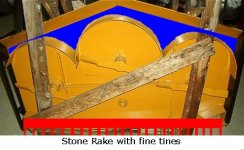

There is at least one possibility that I may stand corrected. If you are saying that the product has been redesigned for 2004 models and is now produced by deep draw stamping, I'll accept your word on that. But the picture above clearly depicts the welded contruction of all the FC finish mower decks imported from Sicma to date.

There is at least one possibility that I may stand corrected. If you are saying that the product has been redesigned for 2004 models and is now produced by deep draw stamping, I'll accept your word on that. But the picture above clearly depicts the welded contruction of all the FC finish mower decks imported from Sicma to date.