I hope someone can help explain;

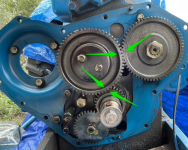

I am installing an injector pump into a Ford 1000. (please see attached manual page 17 and 18). I rotated the crankshaft till the marks matched and are lined up between the crank shaft to the idler pulley and the other marks are lined up between the idler and the camshaft gear (see attached picture).

Seems now we just need to align the injector pump gear to the idler ? But there are no more marks on the idler, both are being used; one for the crank and one for the camshaft.

Perhaps if I rotate to the 21 BTDC as it appears to suggest on page 18:25 this will free up a mark on the idler ?

And I am not clear exactly what we are doing looking for the spill-timing location as in 25:e

Perhaps someone has done this, figured it out, and can help explain

Thanks you in advance (no pun intended)

Rick

I am installing an injector pump into a Ford 1000. (please see attached manual page 17 and 18). I rotated the crankshaft till the marks matched and are lined up between the crank shaft to the idler pulley and the other marks are lined up between the idler and the camshaft gear (see attached picture).

Seems now we just need to align the injector pump gear to the idler ? But there are no more marks on the idler, both are being used; one for the crank and one for the camshaft.

Perhaps if I rotate to the 21 BTDC as it appears to suggest on page 18:25 this will free up a mark on the idler ?

And I am not clear exactly what we are doing looking for the spill-timing location as in 25:e

Perhaps someone has done this, figured it out, and can help explain

Thanks you in advance (no pun intended)

Rick