Villengineer

Gold Member

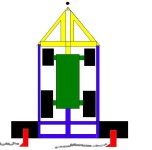

Ah, now this all makes more sense. Knowing the application really helps us help you. Based on your reply it appears that your parameters are blowing 2 windrows approx. 3ft sq on either side of the plow while minimizing the amount of equipment required and minimizing the impact on the "medians". Just off the top of my head I would say that mounting everything on the single loader would increase the impact on the "medians" as your contact psi will be higher. What if instead of mounting the blowers directly to the loader you built a "trailer" that the loader backed into that would essentially be self contained. Most loaders have at least have a hitch. This trailer could be "U-shaped" to keep the OAL as small as possible and bring the blowers up alongside for ease of operator observation. The loader then only has to pull it along. High floatation tires could be used to minimize ground contact pressure and it could have it's own power unit so as not to rob any power from the loader. Since it would be easily removed the loader could still be used as just the plow if need be or as a loader in the off-season. This also wouldn't necessitate the purchase of a new loader.