WagonRanch

Member

- Joined

- Jan 11, 2012

- Messages

- 34

- Location

- Northern California

- Tractor

- Lamborghini R-360; John Deere 870

I've done quite a bit of looking on TBN to learn about gauge wheels and tail gauge wheels because I want to build a gauge of some sort for my 60" Rhino RB.

From what I've seen the addition of a gauge is desirable, but there have been some issues and I'm trying to do this fairly inexpensively yet ruggedly enough to not have to do it over again. I do not have rear hydraulics on ether one of my tractors and don't feel that this modification justifies the additional expense.

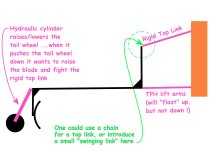

I want the wheel(s) to be adjustable for height, but I'm not sure how critical that adjustment needs to be. With a top link used on a tail wheel the adjustment is infinite; so are trailer screw jacks when used vertically with two wheels. However the tail wheel can get expensive if I go with a wide laminated tire and top link and it increases the length to the point that I think it would be unwieldy in close quarters around buildings. On the other hand the trailer jacks aren't any cheaper and they don't seem to be strong enough if I get the HF cheapies.

With two guide wheels I would have a fair amount of tire patch and am hoping that some of the cheaper wheel/tire combos would hold up. There have been several comments about blowing out pneumatic tires (300lb load rating), but I don't see any solid wheels that would be suitable either. Do the steel wheels offer enough impact resistance without shattering on a rock? What about steel wheels with a thin solid poly or rubber "tire"?

The other problem that I've seen with the vertically mounted guide wheels is that they don't seem to very strong and vertical adjustment has to be done with spacers of some sort if trailer jacks aren't used. I've seen a couple of builds using all-thread, but that stuff isn't very strong in my experience.

So, here are a couple of ideas. One tail dragger, which I'm not loving for the reasons stated above and another with a pair of wheels. I realize that the one with a pair of wheels means that I wouldn't be able to readily use the convex side of the blade even with the wheels removed. Do you think this is an acceptable compromise? I maintain about a mile of gravel road with only occasional periods of snow.

The one with the pair of wheels is adjustable, but only in 2" increments (or whatever spacing I end up with). Is this enough adjustment? Too much hassle (pull four clips and pins, move, line up, replace pins and clips)? How about a gross adjustment with the pins and then spacers for finer adjustments? Seems like overkill to me, but then I've never used gauge wheels so I'm making it up as I go along.

Any ideas and/or suggestions that would help me out?

Thanks!

From what I've seen the addition of a gauge is desirable, but there have been some issues and I'm trying to do this fairly inexpensively yet ruggedly enough to not have to do it over again. I do not have rear hydraulics on ether one of my tractors and don't feel that this modification justifies the additional expense.

I want the wheel(s) to be adjustable for height, but I'm not sure how critical that adjustment needs to be. With a top link used on a tail wheel the adjustment is infinite; so are trailer screw jacks when used vertically with two wheels. However the tail wheel can get expensive if I go with a wide laminated tire and top link and it increases the length to the point that I think it would be unwieldy in close quarters around buildings. On the other hand the trailer jacks aren't any cheaper and they don't seem to be strong enough if I get the HF cheapies.

With two guide wheels I would have a fair amount of tire patch and am hoping that some of the cheaper wheel/tire combos would hold up. There have been several comments about blowing out pneumatic tires (300lb load rating), but I don't see any solid wheels that would be suitable either. Do the steel wheels offer enough impact resistance without shattering on a rock? What about steel wheels with a thin solid poly or rubber "tire"?

The other problem that I've seen with the vertically mounted guide wheels is that they don't seem to very strong and vertical adjustment has to be done with spacers of some sort if trailer jacks aren't used. I've seen a couple of builds using all-thread, but that stuff isn't very strong in my experience.

So, here are a couple of ideas. One tail dragger, which I'm not loving for the reasons stated above and another with a pair of wheels. I realize that the one with a pair of wheels means that I wouldn't be able to readily use the convex side of the blade even with the wheels removed. Do you think this is an acceptable compromise? I maintain about a mile of gravel road with only occasional periods of snow.

The one with the pair of wheels is adjustable, but only in 2" increments (or whatever spacing I end up with). Is this enough adjustment? Too much hassle (pull four clips and pins, move, line up, replace pins and clips)? How about a gross adjustment with the pins and then spacers for finer adjustments? Seems like overkill to me, but then I've never used gauge wheels so I'm making it up as I go along.

Any ideas and/or suggestions that would help me out?

Thanks!

Last edited: