3RRL

Super Member

- Joined

- Oct 20, 2005

- Messages

- 6,931

- Tractor

- 55HP 4WD KAMA 554 and 4 x 4 Jinma 284

I converted my 7' Howse Boxblade during my vacation so that it now has a hydraulic system to raise and lower the scarifiers. I got the idea from other threads I read here and figured it would be a fun project.

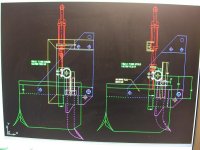

I'll show a lot of pictures (again) to show the new "look" first and then the process of changing it. This project took quite a lot of machining and a little design work to retro-fit everything so it would work properly. Lucky, I was able to do most of the component machining in my shop at home, but much of the welding, fitting and final assembly had to be done at my rural property. My biggest concern was the proper line up of all the leader pin guides, the gears, shaft and racks. I had no way to fixture or bore holes at the property to guarantee perfect association between them.

Here is the first picture of the finished hydraulic system on the boxblade. Notice the handle to move the system manually in the event of a blown hose or cylinder. The handle screws off the end that stays on the shaft and I'll store it in one of the tool boxes on the tractor. All components and gears are keyed to the shaft. Notice the pins that guide the scarifier lift blocks up and down. Also notice that each gear/rack assembly is enclosed to keep the appropriate pitch diameter relationship. Also the clearance through the large black brackets for the system to work.

I also added supports for the lift pins now that the boxblade nears 1,000 lbs in weight. And finally supports around the sides and back of each scarifier to add strength and reduce bending and breaking.

I'll show a lot of pictures (again) to show the new "look" first and then the process of changing it. This project took quite a lot of machining and a little design work to retro-fit everything so it would work properly. Lucky, I was able to do most of the component machining in my shop at home, but much of the welding, fitting and final assembly had to be done at my rural property. My biggest concern was the proper line up of all the leader pin guides, the gears, shaft and racks. I had no way to fixture or bore holes at the property to guarantee perfect association between them.

Here is the first picture of the finished hydraulic system on the boxblade. Notice the handle to move the system manually in the event of a blown hose or cylinder. The handle screws off the end that stays on the shaft and I'll store it in one of the tool boxes on the tractor. All components and gears are keyed to the shaft. Notice the pins that guide the scarifier lift blocks up and down. Also notice that each gear/rack assembly is enclosed to keep the appropriate pitch diameter relationship. Also the clearance through the large black brackets for the system to work.

I also added supports for the lift pins now that the boxblade nears 1,000 lbs in weight. And finally supports around the sides and back of each scarifier to add strength and reduce bending and breaking.