Chilly807

Elite Member

Thanks Chilly,

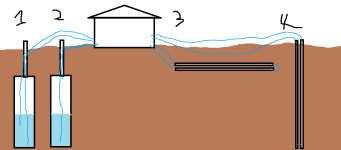

I just spoke to a man who sells the heat pumps. He was nice enough to give me some good time and answered many questions. He's been using a well-dump system for the last 30 years and my well will work with that system. Not sure that I want to do a dump even though I have 20+ gallons per minute flow, I like the idea of running it back to the aquifer. The easiest set up is the dump though and it's very efficient at 175 feet down it's just about right for my 2 ton needs. The dump means I'll be putting about 180 gallons an hour into the dry well, probably a lot less though as the pump will probably only run 15 minutes per hour on most days. Let's see, that comes out to 180/4 or 45 gph. I'll have to think about it.

Rob

Be careful of your water quality, if it's hard at all it'll dramatically shorten the life of your heat exchanger. With a closed loop system you have much better control over the water in it.

Sean