You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Grapple Design Ideas

- Thread starter WhiteRock

- Start date

- Views: 17885

More options

Who Replied?

/ Grapple Design Ideas

#21

DanR67

Silver Member

DanR67

Silver Member

DanR67

Silver Member

DanR67

Silver Member

DanR67

Silver Member

That looks like a good way to get a good feel for your spacing. If that is you cylinder, looks like you should have plenty of room. You cylinder shouldn't be that far down behind your bucket should it?

Have you looked at this design ?

You could also do something simliar to this, and just modify the cylinder mounting.

I think based on your pictures, the angle iron mount will also work.

Looks like in pic 7, you are trying to put your cylinder to far back to me....

What are you cylinder's dimensions?

Have you looked at this design ?

You could also do something simliar to this, and just modify the cylinder mounting.

I think based on your pictures, the angle iron mount will also work.

Looks like in pic 7, you are trying to put your cylinder to far back to me....

What are you cylinder's dimensions?

DanR67

Silver Member

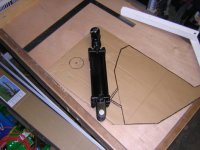

Pic #8 - Last one.

This one shows a template that I made over the winter to work out the best "angle" that I will make the grapple "claws" at. This is before I came up with the cardboard template idea - but same principle - the two pieces of wood are hinged with a 1/4" carriage bolt.

*****************

So the next step is to experiment with layouts. I am mulling over the basic design of the toggle / lever system that will convert the linear motion of the hydraulic cylinder into the rotational motion of the grapple jaw opening / closing. As Whiterock pointed out - I'm concerned about mainly two points:

1) force transmission / strain on bucket (due to size of 3" bore cylinder - pressure reduction valve is a viable work-around)

2) location of cylinder to minimize potential damage

I plan on simply driving in finish nails / screws at the hinge points of the lever templates and observe general grapple opening / closing "movements" & clearances - especially with regard to the cylinder / cross tube.

I guess I forgot to note: I made the template with the bucket fully *curled* - so the cross tube - grapple cylinder should only be critical at that time.

************

I thought that might help kick start some other folks' ideas - and it's a lot easier to cut cardboard than steel! (although I'd debate that cutting steel is likely more fun... /forums/images/graemlins/grin.gif )

Hope that helps,

Dan

This one shows a template that I made over the winter to work out the best "angle" that I will make the grapple "claws" at. This is before I came up with the cardboard template idea - but same principle - the two pieces of wood are hinged with a 1/4" carriage bolt.

*****************

So the next step is to experiment with layouts. I am mulling over the basic design of the toggle / lever system that will convert the linear motion of the hydraulic cylinder into the rotational motion of the grapple jaw opening / closing. As Whiterock pointed out - I'm concerned about mainly two points:

1) force transmission / strain on bucket (due to size of 3" bore cylinder - pressure reduction valve is a viable work-around)

2) location of cylinder to minimize potential damage

I plan on simply driving in finish nails / screws at the hinge points of the lever templates and observe general grapple opening / closing "movements" & clearances - especially with regard to the cylinder / cross tube.

I guess I forgot to note: I made the template with the bucket fully *curled* - so the cross tube - grapple cylinder should only be critical at that time.

************

I thought that might help kick start some other folks' ideas - and it's a lot easier to cut cardboard than steel! (although I'd debate that cutting steel is likely more fun... /forums/images/graemlins/grin.gif )

Hope that helps,

Dan

Attachments

DanR67

Silver Member

WhiteRock -

I have seen the grapple design from ATI - but when I look at their cylinder - if looks fairly compact - even apparently with a fairly decent piston stroke.

I think this design would be tough with the cylinder I have because of it's overall length - IIRC it's @ 19" fully closed - so thats @ 27" with the full 8" stroke extended. I'm not saying it isn't possble - I just have to play around with the layout...My only other concern: the long "support tube" and flanges that bolt to the sides of the bucket must add considerable weight to the design.

Because of the cylinder size (ie 3" bore) and potenttial force it could produce - I was thinking of mounting the cylinder to a "subframe" - a one piece carrier that would absorb all the cylinder force at one end directly - and then perhaps act on a lever at the other end - so that most of the force is not transmitted directly to the bucket...perhaps a bit tough to explain...but also still just a thought. (The "subframe" could be as simple as a deep piece of C-Channel stock that the cylinder could "nest in" for added protection as well.

I'm hoping I'll simply have an "Eureka!" moment while I'm staring at my pile of steel - but I defintiely wanted to mess around with some different "mechanisms" before I got to cutting steel. Thought this would help someone as well...

Dan

I have seen the grapple design from ATI - but when I look at their cylinder - if looks fairly compact - even apparently with a fairly decent piston stroke.

I think this design would be tough with the cylinder I have because of it's overall length - IIRC it's @ 19" fully closed - so thats @ 27" with the full 8" stroke extended. I'm not saying it isn't possble - I just have to play around with the layout...My only other concern: the long "support tube" and flanges that bolt to the sides of the bucket must add considerable weight to the design.

Because of the cylinder size (ie 3" bore) and potenttial force it could produce - I was thinking of mounting the cylinder to a "subframe" - a one piece carrier that would absorb all the cylinder force at one end directly - and then perhaps act on a lever at the other end - so that most of the force is not transmitted directly to the bucket...perhaps a bit tough to explain...but also still just a thought. (The "subframe" could be as simple as a deep piece of C-Channel stock that the cylinder could "nest in" for added protection as well.

I'm hoping I'll simply have an "Eureka!" moment while I'm staring at my pile of steel - but I defintiely wanted to mess around with some different "mechanisms" before I got to cutting steel. Thought this would help someone as well...

Dan

PineRidge

Super Member

It won't work. As soon as it rains the cardboard will get mushy and you'll loose your load. /forums/images/graemlins/wink.gif

Sometimes it's best to just jump in there and start working with the steel.

As long as you just tack weld things together you can still make changes as you go.

And of course there are LOTS of folks here willing to help you if a surprise jumps up.

Go for it............

Sometimes it's best to just jump in there and start working with the steel.

As long as you just tack weld things together you can still make changes as you go.

And of course there are LOTS of folks here willing to help you if a surprise jumps up.

Go for it............

Similar threads

- Replies

- 7

- Views

- 13K