Time for some geometry / trig / hydraulics 101. This is gonna be a long post.....but worth the read if you want an understanding of grapple forces, especially movement about a circular motion.

For starters.....grapple all the way open....and grapple at max close are both the weaker extremes of its range of motion.

Those with a kubota, reference your manual and look at the chart illustrating bucket curl. Either extreme range of motion is the least powerful, because you are rotating the bucket. Same with the grapple. Just look at the triangle and the design of the lid. The more the lid opens....the more the 3 points of the triangle become in alignment....same way with closing.....if it were allowed to close further....there would be a point where the rod end of the cylinder would drop below the line the other two points form. Think about how over-center type latches work (like a chain binder). Same principal.

So for starters.....get familiar with the law of cosines.

Law of Cosines -- from Wolfram MathWorld

I dont have any good side shots of my grapple, but I'll use the drawings but MY dimensions off my tomahawk.

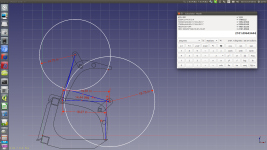

Here is the triangle we are dealing with. Solve for the angle C using law of cosines above....

View attachment 526505

I get 11.8 degrees. A little less than I thought it would be....but more on that later.

So sin(11.8*) = 0.204

So 7850# of force from my 2" bore cylinder multiplied by 0.204 and we get 1601# of force trying to close the lid.

Can do the same thing with the grapple lid open. Dimension C and B stay the same. Dimension A gets 8" smaller (cylinder retracted 8")

View attachment 526508

Get about 10.25 degree angle.

So thats about 1400# of force trying to close the lid.

Now thats at the two extremes. Like I said....its more mid stroke.

Do the same formula....but dimension A (the cylinder).....make it 22.25" to simulate mid stroke of the cylinder and the lid half closed.

That gives you a 15 degree angle....and sin(15*) is 0.259

0.259 x 7850 = ~2000# of closing force.

So, what does all of this translate to in terms of bite force at the teeth.....this is where we get into simple class 3 lever.

The length of my grapple from pivot to tines is 26.25". And we already know the pivot to the point where the force applied is 23"

View attachment 526509

So if at full closed my cylinder being on the 11.8* angle can impart 1600# of force to close the lid, and does so 23" away from the pivot of the lid (fulcrum), how much force can it exert at the tips of the teeth that are 26.25" away from the fulcrum.

Answer = ~1400# of force.

At mid stroke where the 15* cylinder angle allowed for 2000# of force to close the lid, that would be about 1735# of force at the teeth.

I can say that I would not want a grapple with any LESS force at all. So design with that in mind. More force within reason certainly isnt gonna hurt a thing.

And remember, I used YOUR drawings, BUT MY dimensions. So things may not look right, or may not look to "scale" and thats why. I'd be shooting for ~1500-2000# of clamp force.

If anyone has a different brand grapple and would like me to calculate the bite force.....All I need is 4 measurements. Close your grapple lid and give be the 3 dimensions that form the triangle (A,B,and C in my drawings), and then the dimension from the lid hinge to the teeth. And I can calculate assuming a 2" cylinder and 2500psi. See how the geometry of some other grapples compare:laughing: