ejtaylor822

Gold Member

Hey guys,

Sorry for not getting back to everyone.

Was able to finally get the sump off last weekend and tear into it. Very interesting as will show in some following pics. Word to the wise for anyone else that is considering this: follow bluechip’s advice and use an engine hoist or a couple of big, strong friends. I was able to get it off myself, but, if it had been another 2 pounds heavier I couldn’t have budged it! That thing is a beast! Will post my hernia xrays. /forums/images/graemlins/grin.gif

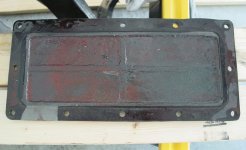

Anyway, first pic is nothing exciting. Just the before and after seat removal. I was surprised how heavy the seat was. (4) bolts that go right into the case. The front (2) are simple to get out with a socket, back (2) take some effort with a wrench.

Sorry for not getting back to everyone.

Was able to finally get the sump off last weekend and tear into it. Very interesting as will show in some following pics. Word to the wise for anyone else that is considering this: follow bluechip’s advice and use an engine hoist or a couple of big, strong friends. I was able to get it off myself, but, if it had been another 2 pounds heavier I couldn’t have budged it! That thing is a beast! Will post my hernia xrays. /forums/images/graemlins/grin.gif

Anyway, first pic is nothing exciting. Just the before and after seat removal. I was surprised how heavy the seat was. (4) bolts that go right into the case. The front (2) are simple to get out with a socket, back (2) take some effort with a wrench.