jwmorris

Veteran Member

- Joined

- Oct 3, 2007

- Messages

- 1,146

I have been interested in PCP air rifles since my daughter was born but didn't like the way folks have to fill them.

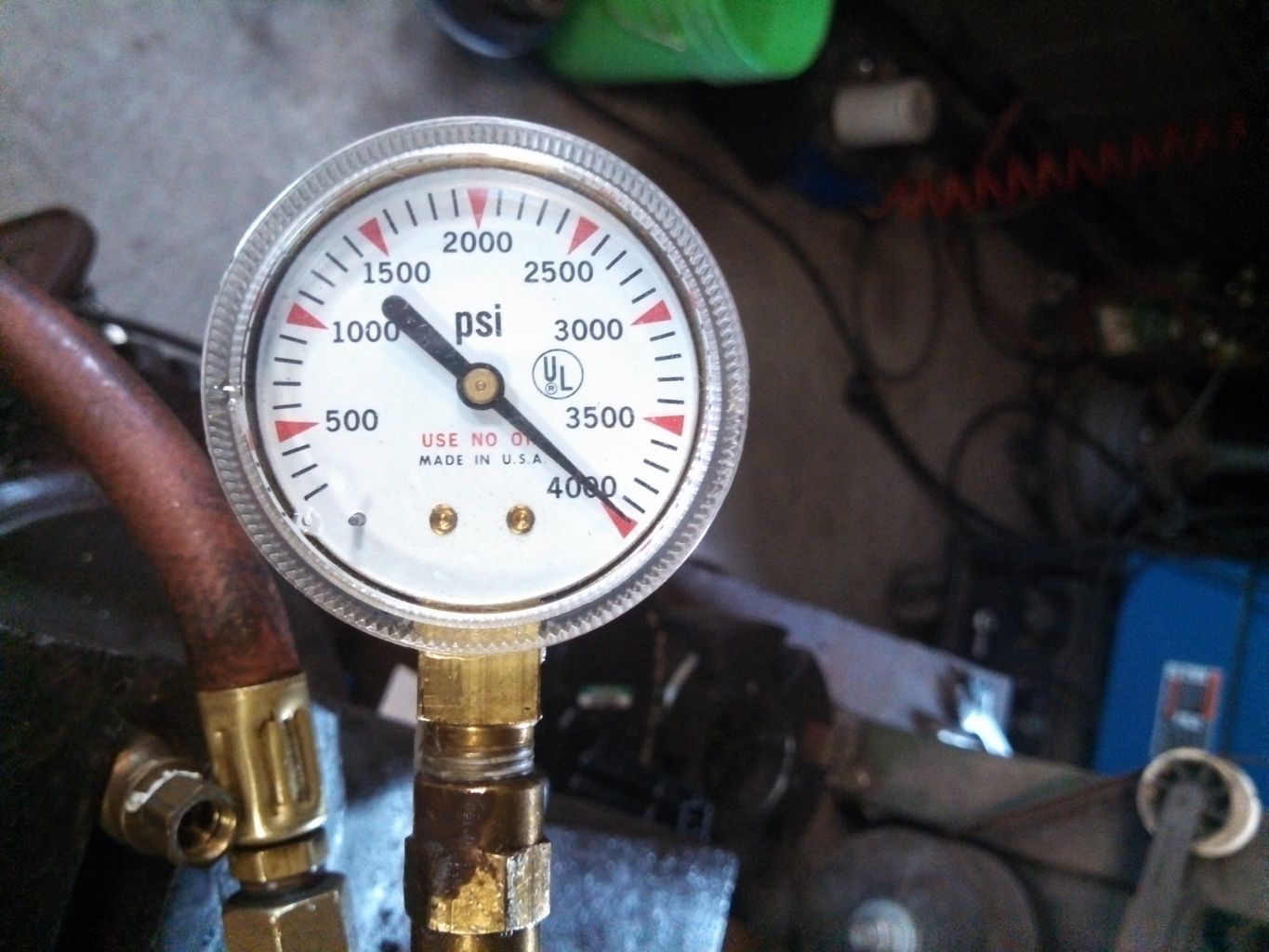

Built a pretty simple booster pump that uses 90 psi "shop" air and boosts my weld tank gasses up from 1500 psi up to the pressures they work at. 2400 psi so far, have to wait on the check valves and 4500 psi tank to get here for further testing.

Built a pretty simple booster pump that uses 90 psi "shop" air and boosts my weld tank gasses up from 1500 psi up to the pressures they work at. 2400 psi so far, have to wait on the check valves and 4500 psi tank to get here for further testing.