Rick,

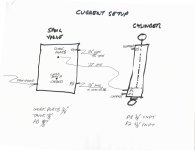

I'd like to address the four hoses that you questioned. Here's the current setup:

Firstly, I don't have rear remotes on this tractor but I do have a Front End Loader and associated spool bank.

So. I tapped into Power Beyond (PB) port on the FEL spool bank. I got the idea reading the installation instructions from those guys that put out after-market remotes kits. It's a poor man's way to tap into the hydraulics.

Looking at the valve spool in my diagram. The "From Pump" line originates from the PB port on the FEL. The PB outgoing line on this valve spool connects to the other end of the line that I interrupted at the FEL.

The "WorkPortB" line is obvious. The "Tank" line goes to the hydraulic fluid filler cap on the tractor - unrestricted. That's four lines.

Why did I do it this way? Trial and error.

Originally I didn't have a PB "adapter" on this spool valve. So I plugged it. I left the Tank port line going straight to the tank on the tractor. Result: same slow up/down but my 3pt stopped working. Well thats a problem because I use the 3pt to adjust the pitch of the PP.

Then I thought about plugging the Tank port and sending all the fluid to the PB port. I caught myself before doing it. No way that line can handle all that dumped fluid.

Okay, so then I thought about plugging the Tank port, remove the PB adapter and pipe all the fluid to the Tank. Internally on the spool valve the Tank and PB port are connected if you remove the PB adapter. Well that resulted in the 3pt not working again -- there way no line returning to the FEL spool bank.

Why do I have four lines? The short answer is I need hydraulic power after this hydraulic tap, in my case the 3pt.

Whew! Remember you asked

Ed